At its core, a hydro jet nozzle is what turns a hydrovac truck's raw power into a precision digging tool. It’s the business end of the whole operation, the single point where pressurized water becomes a focused, soil-slicing jet, essential for any modern hydrovac crew.

The Power Behind Precision Hydrovac Excavation

In hydrovac excavation, the nozzle is the unsung hero. It's the critical component that takes all the potential energy built up by the truck's pump and converts it into a surgical instrument for digging. Think of it like a pressure washer versus a garden hose—the hose just gets things wet, but with the right tip, a pressure washer can strip paint off a wall. Hydro jet nozzles do the same thing for the hydrovac industry, just on an industrial scale.

These nozzles are engineered to take a high-pressure, high-volume flow of water (measured in PSI and GPM) and force it through a tiny, meticulously machined opening. This simple action accelerates the water into a concentrated stream so powerful it can cut through compacted clay, gravel, and dense soils with surprising ease.

A Modern Tool with Deep Roots

While today's hydro jet nozzles are marvels of modern engineering, the idea of using pressurized water to move earth isn't new at all. It actually dates back to the California Gold Rush in the 1850s, when miners used a primitive form of hydro excavation to blast away entire hillsides. An engineer named Edward Matteson rigged up a canvas hose with a large iron nozzle he called a 'monitor.' Fed by gravity, it created an incredibly powerful stream. By 1860, this method was so effective that a single monitor could move an astonishing 1,000 cubic yards of material daily—a 500% improvement over digging by hand.

The Strategic Advantage of Precision Digging

This ability to cut without brute mechanical force is the magic of hydro excavation. Instead of the high-risk, high-impact gamble of swinging a backhoe bucket, a hydro jet nozzle offers a non-destructive way to dig. This is absolutely critical for hydrovac operators working near sensitive underground utilities like:

- Fiber optic cables

- Gas lines

- Water mains

- Electrical conduits

The nozzle lets an operator carefully liquefy the soil around these assets, turning it into a slurry that the vacuum hose can easily suck away. You can learn more about all the pieces that come together in our guide to hydrovac excavation equipment.

A backhoe is a sledgehammer, smashing its way through the ground. A hydro jet nozzle is a scalpel, making precise incisions exactly where needed.

This is precisely where The Hydrovac Attachment Tool shines as the solution for effective digging purposes. It brilliantly combines the high-pressure wand and the vacuum hose into a single, unified tool. This smart design creates a controlled excavation zone right at the nozzle tip, capturing the water and slurry the instant the ground is broken. The result is a cleaner, safer, and much more efficient job with less mess and more control for the operator—it takes a good nozzle and makes it a truly great digging tool.

Comparing Hydro Jet Nozzle Types and Functions

Once you've got a handle on the physics behind hydro jet nozzles, it's time to dive into the specialized tools of the trade. Think of it like a carpenter's toolbox—you wouldn't use a sledgehammer for finish work, and the same principle applies here. The nozzle you choose has a direct impact on your speed, accuracy, and ultimately, the profitability of the job.

In the hydrovac industry, nozzles are generally split into two main camps: static (or fixed) nozzles and rotating (or spinner) nozzles. Each one is engineered to manipulate the high-pressure water stream in a unique way to get a specific result. There are also some highly specialized multi-jet models out there for things like cleaning out pipes or flushing big areas, but for excavation, it’s all about static vs. rotating.

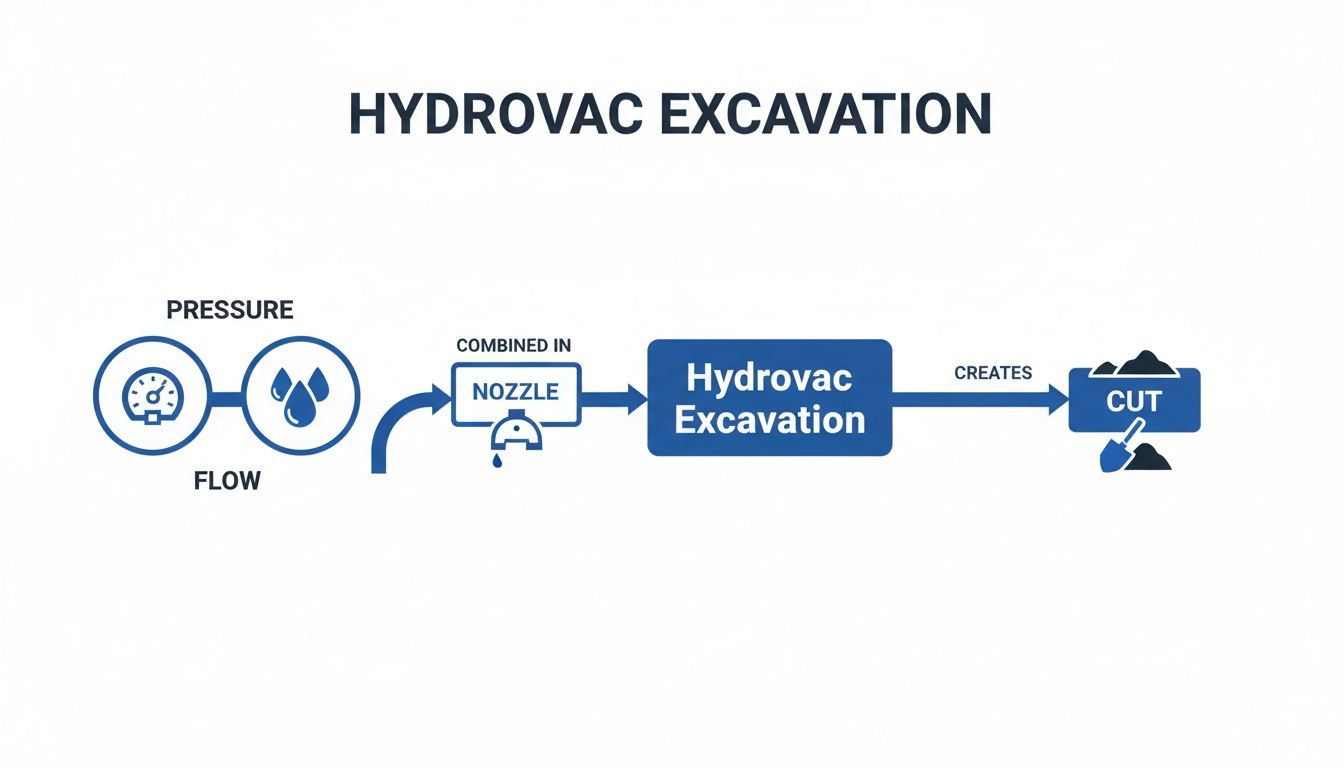

This diagram really nails down the core relationship between pressure, flow, and how the nozzle focuses that power to make the cut.

As you can see, a successful dig is all about balancing the pump's pressure with the right amount of water flow, which the nozzle then channels into a powerful, soil-cutting force.

Static (Fixed) Nozzles

Static nozzles are the workhorses for any hydrovac job that demands precision. They have a fixed opening that shoots a single, laser-focused stream of water. Imagine a concentrated beam of energy designed for surgical accuracy.

Because they focus all their power into one tiny spot, static nozzles are the go-to for delicate work.

- Potholing: They're perfect for carefully exposing underground utilities without nicking a gas line or fiber optic cable. That concentrated stream can slice through tough soil right next to a sensitive asset.

- Daylighting: When you need to verify the exact location and depth of a buried pipe or conduit with minimal ground disturbance, a static nozzle is your best friend.

This is precisely why our Hydrovac Attachment Tool is such an effective solution. It’s designed to contain that intense, localized spray from a static nozzle, which eliminates messy splashback and funnels the slurry directly into the vacuum hose, making the entire digging process cleaner and faster.

Rotating (Spinner) Nozzles

On the other hand, rotating or spinner nozzles are built for bigger, more aggressive digging. Inside the nozzle head, small jets spin at high speed, creating a cone-shaped or circular spray pattern. Instead of hitting the soil at a single point, it attacks it from multiple angles at once.

The action is less like a precise cut and more like a powerful, wide-area scrubbing motion. Those spinning jets are fantastic at breaking up compacted material over a larger surface, making them incredibly efficient for bulk soil removal.

A static nozzle is like a scalpel, designed for making clean, precise cuts for utility locating. A rotating nozzle is more like a power sander, built to strip away material over a wider area for trenching.

Their broad spray pattern is a game-changer for jobs like trenching, where the goal is simply to move a lot of dirt, fast. They also excel at clearing out larger areas for things like foundation prep or remediation projects.

The idea of tweaking nozzles for better performance isn't new. In fact, a major leap happened back in the 1930s when an inventor named Elmo Smith had the brilliant idea to add abrasives to the water stream. This innovation turned a simple water blast into a cutting tool that could slice through stone and metal. Smith's grit-infused, high-pressure streams could chew through wood 300% faster than saws—a powerful early example of nozzle innovation. You can learn more about the history of this kind of tool by checking out the article on water jet cutter technology on Wikipedia.

And if you're working on more specialized cleaning jobs, our deep dive on sewer jetter nozzles is a great resource.

Hydro Jet Nozzle Types and Ideal Applications

To make it even clearer, let's break down the most common nozzle types you'll encounter on a hydrovac job site. Each one has a specific design that makes it the right tool for certain tasks.

| Nozzle Type | Spray Pattern | Primary Function | Best For |

|---|---|---|---|

| Static (0°) | Single, solid stream | Precision cutting & digging | Potholing, daylighting utilities, cutting through hardpan or frost |

| Rotating (Spinner) | Conical or circular spray | Bulk soil removal & area clearing | Trenching, piling hole excavation, surface cleaning, removing sediment |

| Flushing Nozzle | Wide, flat fan spray | Surface cleaning & rinsing | Washing down equipment, cleaning spills, flushing out trenches or culverts |

| Penetrator Nozzle | Multiple forward-facing jets | Clearing blockages | Breaking up tough clogs in pipes or drains (more common in jetting) |

Choosing between a static "pencil tip" for delicate utility locating and a rotating spinner for ripping through soil for a trench is the kind of decision that separates the pros from the rookies. Knowing your nozzles is fundamental to working safely and efficiently in the hydrovac industry.

How to Select the Right Nozzle for Any Hydrovac Job

Choosing the right hydro jet nozzle isn’t about finding the single “best” one—it’s about matching the tool to the task in front of you. Think of it as a strategic decision that directly impacts how fast, safe, and profitable your day is. This choice always comes down to balancing three key factors: the soil you’re up against, the scope of the job, and the specs of your hydrovac truck.

It’s a lot like picking the right drill bit. You wouldn't try to punch through concrete with a bit made for soft pine, and the same principle applies here. Getting the nozzle right from the start means you’re not just wasting fuel and water, but you’re also avoiding costly damage to underground utilities. The goal is to find that sweet spot between aggressive digging and precise, controlled excavation.

Analyzing Soil Conditions and Project Scope

The very first thing you need to do is get a feel for the ground you’re about to cut. Soil is rarely the same from one job site to the next, and its makeup determines how much force you’ll need to turn it into a slurry. The job itself—whether it's carefully locating a fragile utility or just hogging out a trench—will narrow down your options even further.

-

Loose or Saturated Soils (Sand, Silt, Mud): When the ground is soft, your main challenge isn't cutting, it's flushing. A nozzle with a wider spray pattern, like a rotating or fan-jet nozzle, is perfect for moving a lot of material without a ton of force.

-

Compacted or Rocky Soils (Clay, Hardpan, Gravel): This is where you need raw cutting power. A 0-degree static nozzle is your go-to, focusing all your pump’s energy into a single, intense stream that can penetrate and break apart tough ground.

-

Frozen Ground: Digging in frost calls for maximum, concentrated force. A static, straight-stream nozzle is really the only way to go, delivering the high-impact energy needed to chip away at frozen earth.

The scope of the project is just as critical. If you're potholing to daylight a sensitive fiber optic line, you need surgical precision. A static nozzle gives you that pinpoint control. On the other hand, if you're trenching across a field, you need speed and volume, making a rotating nozzle a much more efficient choice.

Matching Nozzles to Equipment Capabilities

The final piece of the puzzle is your hydrovac truck itself, specifically its PSI (Pounds per Square Inch) and GPM (Gallons Per Minute) ratings. A mismatched nozzle won't just perform poorly; it can put a serious strain on your equipment and create safety risks.

Selecting a nozzle is about creating harmony between the pump, the ground, and the job. A nozzle that's too small for your GPM can cause dangerous pressure spikes, while one that's too large will feel weak and ineffective, wasting time and water.

This is where the nozzle's orifice size is so important. That tiny opening is everything. It has to be sized correctly for your pump’s flow and pressure to get peak performance. Most manufacturers provide charts to help operators pair the right nozzle to their truck, ensuring the whole system runs smoothly and efficiently.

Real-World Scenarios and Solutions

Let's walk through how this works on a couple of common hydrovac jobs.

-

Scenario 1: Exposing a gas line in compacted clay.

- The Challenge: You need a lot of cutting power to get through the clay, but you absolutely cannot risk damaging the utility. Precision is everything.

- The Solution: A static (0-degree) nozzle is the clear winner here. Its focused jet will slice through the tough soil while giving the operator the control needed to work safely around the line.

-

Scenario 2: Clearing a large, shallow area of saturated mud for a foundation pad.

- The Challenge: The ground is already soft, so the goal is to move a high volume of muck over a wide area as quickly as possible.

- The Solution: A rotating (spinner) nozzle is perfect for this. Its wide, conical spray pattern efficiently breaks up and flushes the mud without the intense, focused power of a static jet.

In both of these situations, pairing your nozzle with The Hydrovac Attachment Tool provides a superior solution. For that delicate gas line job, the attachment contains the high-pressure spray, preventing the surrounding soil from collapsing and keeping the utility clearly visible. When clearing that muddy site, it channels the messy slurry straight into the vacuum hose, which dramatically cuts down on site cleanup and keeps the operator and the area much cleaner. It transforms any nozzle into a self-contained, highly efficient digging system.

Maximizing Performance with the Hydrovac Attachment

Picking the right hydro jet nozzle is a huge part of getting the job done, but it’s only half the story. To really get the most out of your gear, you need a system that amplifies its power, tames the chaos of high-pressure digging, and makes your entire workflow smoother. This is exactly where The Hydrovac Attachment Tool comes in—it’s the definitive solution for any nozzle you pair it with.

At its core, this tool brilliantly solves the classic headaches of hydro excavation: the mess, the poor visibility, and the wasted time. By combining the pressure washer wand and the vacuum hose into a single, patented unit, it creates a self-contained excavation zone right where the work is happening. It turns a messy, two-step process into one clean, synchronized action.

Creating a Controlled Excavation Zone

The real magic of the Hydrovac Attachment is how it manages the slurry the very instant it's created. As your nozzle turns soil into liquid, the attachment’s design funnels that mix of water and debris straight into the vacuum hose. This simultaneous cutting and suction brings some massive benefits to the job site.

First off, it almost eliminates splashback. Instead of high-pressure water and mud flying everywhere, the slurry is captured and whisked away. This keeps you, your equipment, and the surrounding area so much cleaner, which means less time spent on cleanup at the end of the day.

It also gives the operator a crystal-clear view of the work. With no muddy spray to block your sight, you can easily see the utility line you're exposing. That kind of precision is absolutely critical for preventing expensive and dangerous strikes on underground infrastructure.

The Evolution of Nozzle Efficiency

The constant push for better efficiency and control has driven nozzle technology for decades. By the 1970s, hydro jetting was already proving itself on tough industrial jobs. It was innovators like Mohamed Hashish, who patented the abrasive waterjet (AWJ) in 1980, that really pushed things forward by developing mixing tubes that quadrupled nozzle life from minutes to hours. That breakthrough, combined with high-pressure intensifiers, made cutting through steel a reality.

For today’s hydrovac pros, this history of innovation means modern attachments paired with advanced nozzles can vacuum debris with up to 90% efficiency and cut utility exposure times by as much as 55%. It's why crews in landscaping and municipal work demand systems that can slash splashback by 80% while holding up to constant abuse. You can get a deeper look into this history by exploring the evolution of waterjet cutting technology at TechniWaterjet.com.

The Hydrovac Attachment doesn't just hold your tools together; it integrates them into a single, cohesive system that captures energy and material at the source, preventing waste and maximizing productive output.

This leap in contained performance is exactly what The Hydrovac Attachment delivers. It takes the raw power of your nozzle and focuses it with an incredible level of control, making it the superior solution for all digging purposes.

A Step-by-Step Guide to Integration

Getting the Hydrovac Attachment set up is a quick, straightforward process designed for the field. It’s a simple, three-part system that connects your existing gear in just a couple of minutes.

- Attach the Base: The main connector slides right over a standard 2.5-inch wet vac hose, giving you a solid foundation.

- Secure the Wand: Your pressure washer wand, with your chosen nozzle already on it, snaps securely into the channel built into the base.

- Lock It In: A heavy-duty clamp tightens down over the hose, holding the whole assembly together as one rock-solid unit.

This easy setup means any operator can quickly turn their standard equipment into a high-performance, low-mess digging machine. The power of your hydrovac’s pump and vacuum are now perfectly in sync. If you want to dive deeper into how these systems work, you can learn more in our article covering vac truck pumps.

Built from a tough, industrial-grade polymer, the attachment is engineered to handle the harsh realities of daily hydrovac work, delivering faster, cleaner, and safer results on every single job.

Essential Nozzle Safety and Maintenance Practices

In the high-stakes world of hydrovac excavation, you're working with water pressure that can easily top 3,000 PSI. At that level, safety isn't just a talking point—it's the absolute foundation of your entire operation. The same incredible power that lets a hydro jet nozzle tear through compacted soil can be devastating if it’s mishandled. A disciplined approach to safety and regular maintenance is non-negotiable. It's how you protect your crew, your equipment, and the public.

Cutting corners on this stuff doesn't just invite a catastrophic failure; it kills your bottom line. A worn-out or neglected nozzle performs so poorly it can double your time on a job, just burning through fuel, water, and labor hours.

Critical Safety Protocols on the Job Site

Before a single drop of water is sprayed, every operator on site needs to know these protocols by heart. These aren’t suggestions—they are the hard-and-fast rules that prevent life-altering injuries.

-

Personal Protective Equipment (PPE) is Mandatory: Don't even think about firing up the pump without the right gear. That means steel-toed waterproof boots, high-impact safety glasses or a full face shield, and waterproof gloves. Depending on the job, a hard hat and high-vis clothing are a must.

-

Maintain a Safe Operating Distance: Keep a healthy distance from the business end of that nozzle. The cutting stream can cause brutal lacerations or injection injuries if it makes contact with skin. Never, ever point the wand at another person, even if you think the system is off.

-

Understand Pressure Limits: Every single component in your setup—from the nozzle and wand to the hose and fittings—has a maximum pressure rating. Make sure they can all handle what your pump is putting out. Pushing past those limits is asking for an explosive component failure.

This is where a system like The Hydrovac Attachment Tool really shines from a safety perspective. By keeping the high-pressure spray and debris inside a controlled zone, it drastically cuts down on dangerous splashback and flying debris. It simply creates a much safer, more predictable environment for the operator.

A hydrovac wand is not a toy. Treat it with the same respect you would any powerful cutting tool. A moment of carelessness can have permanent consequences.

Actionable Maintenance for Longevity and Performance

Want your nozzles to last and perform at their peak? It all comes down to consistent maintenance. A simple routine can save you from costly downtime and protect your bigger investments, like the water pump on your truck.

A well-cared-for nozzle is a reliable, profitable tool. Plain and simple.

Daily Nozzle Inspection Checklist

A quick, 60-second check before each shift can catch a small problem before it turns into a job-stopping headache.

- Check for Visible Damage: Look for any cracks, chips, or weird deformities on the nozzle body itself. A damaged nozzle is a ticking time bomb and needs to be replaced immediately.

- Inspect the Orifice: Take a close look at the nozzle’s opening. High-pressure flow will eventually wear down and enlarge the orifice. When that happens, your pressure drops and you're left with a sloppy, useless spray pattern.

- Ensure a Secure Connection: Give it a twist. Make sure the nozzle is threaded tightly onto the wand and check that any o-rings or seals are in good shape and not leaking.

A worn-out nozzle is more than just inefficient; it's a liability. It wastes time and water and creates unpredictable spray patterns that could easily damage a nearby utility line. Following these simple safety and maintenance steps ensures every hydro excavation job gets done efficiently, profitably, and—most importantly—safely.

Troubleshooting Common Issues in the Field

No matter how good your crew or your gear is, things go wrong on a hydrovac site. When your cutting power suddenly tanks, the first place you should look is right at the tip of your wand: the nozzle. Being able to spot and solve nozzle problems on the fly is what separates a frustrating, money-losing day from a productive one.

Most of the headaches you'll run into out there boil down to just a handful of common culprits. Once you know what to look for, you can get back to digging without burning daylight.

Diagnosing Sudden Pressure Loss

This is the big one. One minute you're slicing through tough soil, the next your powerful jet feels like a glorified garden hose. A sudden drop in pressure grinds the whole operation to a halt.

- Worn Nozzle Orifice: This is culprit number one, without a doubt. Over time, that high-velocity stream of water, often mixed with grit, literally sands away the inside of the nozzle orifice. As that hole gets bigger, your pressure plummets. Your surgical tool has just turned into a blunt instrument.

- Incorrect Pump Settings: It sounds simple, but you'd be surprised how often it happens. Before you start tearing things apart, do a quick sanity check to make sure the pump pressure wasn't accidentally dialed back.

- Internal Debris or Clogs: All it takes is one small pebble or a bit of gunk to get stuck inside the nozzle. That obstruction will kill your flow and make the pressure drop like a rock.

A loss of just 10% in pressure from a worn-out nozzle can easily add 20% or more to your job time. Checking your nozzles isn't just about maintenance—it's about protecting your bottom line.

Solving Inconsistent Spray Patterns

You're expecting a tight, pencil-thin stream, but instead, you're getting a wild, erratic spray. A messy spray pattern doesn't just slow you down; it's a major safety hazard. You lose all precision, which is the last thing you want when digging around a live utility.

- Damaged or Chipped Orifice: The slightest nick or chip on the edge of the orifice can throw the water stream completely off-kilter. This can be incredibly dangerous, turning a precise cutting tool into an unpredictable weapon.

- Partial Clogs: Just like with pressure loss, a partial clog won't stop the flow entirely, but it will warp it. The water is forced around the obstruction, creating a weak, lopsided, and useless pattern.

Addressing Accelerated Wear and Tear

Finding yourself replacing nozzles way too often? If you're burning through them, it’s time to look at what you're feeding your system or how you're running it.

- Poor Water Filtration: Sucking water straight from a pond or an unfiltered hydrant is asking for trouble. You're pumping sand, sediment, and other abrasives right through your system. These particles act like liquid sandpaper, scouring your nozzles from the inside out.

- Operating Above Rated PSI: Pushing your system past the nozzle's recommended pressure rating is a surefire way to destroy it. It might seem like you're getting more power in the short term, but you're just drastically shortening the nozzle's lifespan.

This is an area where a tool like The Hydrovac Attachment Tool can indirectly help. By creating a self-contained cutting area, it minimizes the amount of loose debris that can be kicked up and potentially damage the nozzle tip. Its straightforward, tough-as-nails design also means there are fewer moving parts to fail, simplifying the whole troubleshooting process when a problem does pop up.

Common Questions from the Field

Getting out on a job site always brings up questions. To help you get the most out of your hydro jet nozzles, we've put together answers to some of the things we hear most often from operators like you.

What's the Real Difference Between PSI and GPM?

Think of it this way: PSI (Pounds per Square Inch) is the muscle, and GPM (Gallons Per Minute) is the mover.

PSI is the sheer force behind the water jet. It's what gives you the power to slice through tough, compacted soil or break up stubborn blockages. GPM, on the other hand, is all about volume—it’s the amount of water flowing out to wash away all the debris you just broke loose.

You need high PSI for hard ground, but you need high GPM to clear the area efficiently. The sweet spot for any hydrovac job is finding the right balance between the two.

How Often Do I Really Need to Replace My Nozzles?

There's no single answer here, as it really boils down to how you work. The lifespan of your nozzle depends on your total operating hours, the quality of your water (gritty water wears them out faster), and the pressures you're running.

The best practice is to give your nozzle a quick visual inspection before every shift. Look for any cracks, visible wear, or—most importantly—any sign that the orifice is getting wider.

If you notice a sudden drop in performance or see the spray pattern looking weak and inconsistent, that’s your nozzle telling you it’s time for a change. For most operators running their equipment regularly, swapping out nozzles every 3-6 months is a good rule of thumb to keep everything running safely and at peak performance.

Can I Use My Favorite Nozzle with the Hydrovac Attachment?

Absolutely. We designed The Hydrovac Attachment Tool to be as versatile as possible. It connects right to your standard pressure washer wand, so it works with the vast majority of hydro jet nozzles on the market.

The only thing you need to double-check is that the nozzle you're using is rated for your pump's specific PSI and GPM output.

The real benefit is how the attachment elevates the performance of whatever nozzle you choose. It contains the high-pressure spray, virtually eliminating splashback and keeping your view of the dig site clear. This means any nozzle you hook up becomes a more precise, controlled, and safer tool for excavation.

Ready to make your hydrovac work cleaner, safer, and more efficient? The patented system from Hydrovac Attachment integrates your tools into a single, high-performance unit. Discover how to upgrade your excavation process today at hydrovacattm.com.