In the world of hydrovac operations, where precision and reliability are everything, stainless steel camlock fittings are the unsung heroes. They’re the go-to solution for connecting hoses and tools, especially when you’re dealing with high-pressure systems. Imagine a crew daylighting utility lines on a busy city street—every connection needs to be fast and absolutely leak-proof. The right fittings mean less downtime and safer digs, which goes straight to the bottom line. For effective, pinpoint digging, tools like the Hydrovac Attachment Tool depend on these robust connections to deliver results.

Why Stainless Steel Camlocks Are a Must-Have for Hydrovac Crews

For any hydrovac crew, efficiency isn't just about moving fast; it's about knowing your gear won't fail you. Think of stainless steel camlocks like the carabiners for a professional climbing team. They’re the critical link that has to work perfectly under serious strain, securing your lifelines so you can move quickly and with confidence.

That’s exactly what a hydrovac operator needs. Whether you're potholing for utilities or trenching in a tight spot, you rely on camlocks to create a fast, secure, and totally leak-proof seal between your hoses and tools. When every second counts, you can't be messing with faulty connections.

The Real-World Impact on Job Site Performance

The speed and dependability of these fittings have a direct and measurable impact on the job. A connection that snaps shut in seconds means your crew spends less time on setup and more time actually digging. This kind of efficiency is what modern hydrovac excavation equipment is all about, because minimizing prep time is key to maximizing profit. This focus on efficiency is precisely why tools like the Hydrovac Attachment Tool are becoming industry-standard solutions for effective digging.

And it’s not just our industry seeing the value. The global camlock fittings market hit $2.7 billion in 2023 and is on track to reach $4.5 billion by 2030. That massive growth is coming from industries like construction and oil & gas, where performance under pressure is non-negotiable.

Built to Survive Tough Field Conditions

Let's be honest—hydrovac work is brutal on equipment. Your gear is constantly getting blasted with mud, water, and abrasive grit that would chew through lesser materials in no time. This is where stainless steel really shines, with its unmatched resistance to corrosion and abrasion.

In the wet, slurry-filled environments we work in every day, stainless steel can reduce potential failure rates by up to 40% compared to materials like aluminum. That durability keeps your connections tight, prevents costly leaks, and helps maintain a much safer work area.

It's also worth noting how important it is for equipment to be sealed against the elements, which is why standards like understanding IP67 ratings are becoming more common. The natural toughness of stainless steel is a perfect fit for these demands. It’s exactly this kind of resilience that makes them a core component for tools like The Hydrovac Attachment, which needs a solid, leak-free connection to deliver precise, low-mess excavation. This tool is the ideal solution for effective digging purposes, leveraging the strength of stainless steel to ensure reliability.

Choosing Your Steel: 304 vs. 316 Grade Camlocks

When you're outfitting your hydrovac truck, picking between Grade 304 and Grade 316 camlock fittings stainless steel isn't just a minor detail—it's a critical decision that directly affects your equipment's lifespan and your crew's reliability on the job. Think of it like choosing tires for a work truck. A solid all-terrain tire gets you through most days, but for serious mud and muck, you need something specialized. The same logic applies here.

Grade 304 is the industry's go-to, the tried-and-true workhorse. It’s tough, dependable, and offers fantastic corrosion resistance for the vast majority of hydrovac jobs you'll encounter. For day-to-day work sucking up water, soil, clay, and general construction debris, 304 hits the sweet spot between performance and cost. It's the reliable standard for everything from municipal daylighting to digging trenches in a new subdivision.

But we all know not every job site is that straightforward. That’s where Grade 316, the specialist, earns its keep.

When to Upgrade to Grade 316 Stainless Steel

What makes Grade 316 different? It’s a single, powerful ingredient: molybdenum. This element gives 316 stainless steel a massive leg up in fighting off chlorides, salts, and aggressive industrial chemicals. While it might cost a bit more upfront, that investment pays for itself by preventing premature failure when conditions get nasty.

So, when should you reach for the 316s? Here are a few classic hydrovac scenarios where it's the only smart choice:

- Industrial Site Cleanups: Think chemical plants, refineries, or manufacturing facilities. If you’re cleaning up a spill, you have to assume you're dealing with acids or other corrosive gunk.

- Coastal or Winter Operations: Digging anywhere near the coast means constant exposure to saltwater spray. Likewise, winter roadwork involves sucking up slush loaded with corrosive de-icing salts.

- Wastewater and Agricultural Jobs: These materials often have unique chemical makeups that are far more aggressive than plain old dirt and water.

Trying to get by with a 304 fitting in these environments is a gamble. The constant chemical attack can cause pitting and corrosion, eventually compromising the seal and leading to a failure. A blown fitting doesn't just mean downtime; it can be a safety hazard. The added shield of a 316 fitting isn’t a luxury—it’s essential insurance for your equipment and your crew.

Choosing the right grade is an investment in operational uptime. For high-corrosion environments, a Grade 316 fitting can last up to 50% longer than its 304 counterpart, making it the most cost-effective solution in the long run.

A Head-to-Head Comparison

To lay it out simply, let's compare these two grades side-by-side. This quick-reference table should help your crew instantly know which fitting is the right tool for the job.

Comparing 304 vs. 316 Stainless Steel Camlock Fittings

| Feature | Grade 304 Stainless Steel (The Workhorse) | Grade 316 Stainless Steel (The Specialist) |

|---|---|---|

| Primary Use Case | General hydrovac operations, including water, slurry, and standard debris. | Environments with high salinity, chlorides, or industrial chemicals. |

| Key Alloy Element | Chromium and Nickel | Chromium, Nickel, and Molybdenum |

| Corrosion Resistance | Excellent resistance to standard environmental corrosion and oxidation. | Superior resistance to pitting corrosion from chlorides and acids. |

| Ideal Job Site | Municipal utility locating, residential trenching, general construction. | Industrial plant maintenance, coastal area excavation, winter roadwork. |

| Cost | More economical and widely available for everyday applications. | Higher initial investment, justified by extended lifespan in harsh conditions. |

At the end of the day, a well-equipped hydrovac truck is ready for anything. Your Grade 304 fittings will handle the bulk of your work, no question. But having a set of Grade 316 camlocks on hand means you're prepared for those specialized, high-stakes projects that others might have to turn down.

This foresight not only protects your gear but also builds your reputation as a crew that’s ready for any challenge. It's especially important when you’re using precision tools like The Hydrovac Attachment, where the integrity of every single connection is vital for digging effectively and keeping the site safe.

Getting to Grips with Camlock Types and Sizes

When you're out in the field, making the right connection fast is everything. The best way to think about a camlock system is as a heavy-duty "plug and socket." You have a male adapter (the plug) that slides into a female coupler (the socket). Flip the arms down on the coupler, and you've got a tight, secure seal in seconds. It’s that simple.

Getting this basic concept down is the first step to eliminating frustrating leaks and making sure your gear, including tools like The Hydrovac Attachment Tool, works exactly as it should. This tool is a prime example of a solution designed for effective digging purposes.

The whole system is broken down by letters—usually A through F, plus a DC (Dust Cap) and DP (Dust Plug). Each letter tells you exactly what you're holding: whether it's a male or female end and what kind of connection it has on its backside, like threads or a hose shank. Your only job is to pair them up correctly. A male adapter always goes into a female coupler. It’s a beautifully simple system designed for speed, but grabbing the wrong type will bring a job to a dead stop.

Decoding the Camlock Alphabet

Let's walk through the most common types you’ll see on a hydrovac truck. Knowing what each one does is absolutely essential for building the right hose assembly or hooking up a new tool on the fly.

- Type A: This is your male adapter with female threads. It’s perfect for screwing onto a male-threaded pipe or valve to give you a quick-connect male end.

- Type B: This is the female coupler with male threads. You’ll often find this on the end of a pump or a tank outlet, ready to accept a hose with a male adapter.

- Type C: This is the female coupler with a hose shank. This is a workhorse. You slide your hose over the barbed shank, clamp it down, and you’ve got a female connection point right on the end of your hose.

- Type D: Think of this as the female coupler with female threads. It’s the go-to for adding a quick-connect female end to any male-threaded outlet.

- Type E: This is a male adapter with a hose shank. It’s probably the most common fitting you'll see on the end of a hydrovac hose, letting it plug right into a female coupler on a tank or another tool.

- Type F: And finally, the male adapter with male threads. This one is great for converting a female-threaded connection into a male quick-connect point.

Mismatched types are one of the biggest—and most avoidable—headaches on site. Trying to connect a Type A to a Type F, for instance, is a no-go. They're both male adapters. You always need a male-female pairing, like plugging a Type E into a Type D, or a Type A into a Type C.

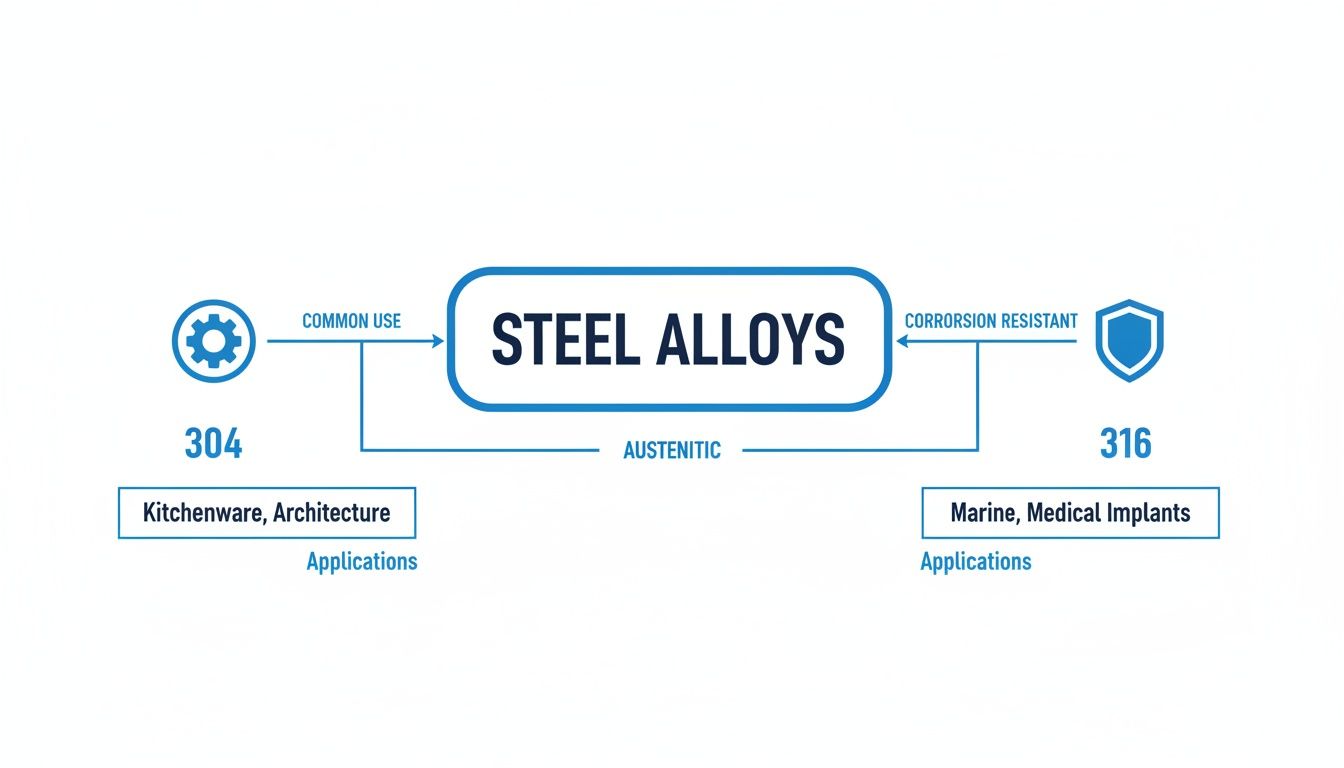

This diagram shows the two main stainless steel grades used for these fittings, which is another key part of the puzzle.

As you can see, 304 steel is the tough, all-around performer. But when you’re dealing with harsh chemicals, road salt, or other corrosive materials, upgrading to 316 is a smart move that pays for itself.

Why Size and Thread Standards Are Non-Negotiable

Beyond the letter type, the size of your camlock fittings stainless steel is just as important. Camlock sizes are measured by the inner diameter of the hose or pipe they're designed for, typically running from ½ inch all the way up to 6 inches for serious industrial work.

It's simple: a 3-inch fitting connects to another 3-inch fitting. There’s no forcing it. Using the wrong size is either physically impossible or, worse, it will create a massive leak the second it's put under pressure.

Just as critical are the thread standards. For any camlock with threads (Types A, B, D, and F), you’re almost certainly going to run into one of two types here in North America:

- NPT (National Pipe Thread): This is the king in the United States and Canada. NPT threads are tapered, so they wedge together as you tighten them, helping create a strong mechanical seal.

- BSP (British Standard Pipe): This is the standard across Europe, Asia, and Australia. BSP threads run parallel and rely on a gasket or an O-ring to do the sealing.

Trying to mix NPT and BSP threads is a recipe for disaster. They might catch for a turn or two, making you think you have a connection, but they will never create a proper seal. Worse, they'll strip the threads as soon as you apply any real force. Always double-check the thread type on your existing equipment before ordering new parts.

Connecting the Hydrovac Attachment Tool

This all becomes crystal clear when you're integrating specialized gear like The Hydrovac Attachment Tool. The tool itself is built to fit a standard 2.5-inch wet-vac tube, but your main hydrovac hose might be larger—say, 3 or 4 inches. To bridge that gap, you need the right combination of reducers and camlock fittings stainless steel.

For example, you might have a 3-inch Type C female coupler on your main vacuum hose. To connect the tool, you'd use a reducer that steps down from 3 inches to 2.5 inches, finishing with a 3-inch Type F male adapter. That adapter then plugs directly and securely into your hose's coupler.

This kind of setup gives you a solid, leak-proof connection that lets the tool do its job right. If you want to dive deeper into different ways to adapt hoses, check out our guide to shop vac hose fittings. By taking a minute to map out your connection points and match the types, sizes, and threads, you ensure every part of your system works together safely and efficiently.

Staying Safe: Why Pressure and Temperature Ratings Matter

When you're out on a hydrovac job, the PSI and temperature ratings on your stainless steel camlock fittings are more than just numbers stamped on metal. Think of them as the absolute red line on a tachometer. Pushing past them is a gamble, and it's one that can lead to catastrophic failure on site.

Understanding these limits is fundamental to safe operation. The maximum working pressure of a fitting isn't some static number pulled from a lab. It's a dynamic value that changes based on what’s happening right there on your job site. The fitting's size, the ambient temperature, and even the type of gasket you've installed all have a say in how much pressure your connection can actually handle.

For example, smaller fittings can take more pressure than their larger counterparts. A 2-inch stainless steel camlock might be rated for 250 PSI, but a 4-inch version of the exact same design could top out at 150 PSI. Why the difference? The larger surface area of the 4-inch fitting means there’s a lot more force trying to blow that seal apart.

How Job Site Conditions Change the Game

Temperature throws another wrench in the works. In the dead of winter, extreme cold can make gaskets brittle and prone to cracking, creating a prime opportunity for a leak. On the flip side, scorching summer heat can cause them to soften, potentially squeezing them out of place under pressure. This is precisely where stainless steel proves its worth. Unlike aluminum or plastic, it holds its ground across a huge temperature range, keeping things together whether you're digging in a blizzard or a heatwave.

A sudden pressure spike from a clog is a hydrovac operator's nightmare. That surge can easily blow past the limits of a weaker fitting, leading to a dangerous hose blowout. The incredible tensile strength of stainless steel gives you a critical safety buffer, preventing it from deforming or failing when you need it most.

This is especially critical for crews using versatile tools like The Hydrovac Attachment Tool for trenching or setting fence posts. In the controlled chaos of vacuum excavation, you need connectors built for both speed and brute strength. It's no surprise that in demanding utility sectors across North America and Europe, adoption of stainless steel camlocks has climbed over 50%. They consistently handle pressures up to 250 PSI without warping, which has cut leak-related incidents by a reported 30% compared to older brass options. This isn't a new trend, either—U.S. manufacturing of these fittings ramped up in the 1980s for oilfield work, where stainless steel's resistance to saltwater corrosion saved companies millions in downtime. You can dig deeper into the rise of camlock technology on accio.com.

What This Looks Like in the Real World

Let's walk through a couple of common field scenarios to see what happens when these limits are ignored.

-

The Overpressure Event: Your crew is daylighting a utility line and hits a thick chunk of clay, instantly clogging the hose. The vacuum pump doesn't stop, and pressure spikes way beyond the normal operating range. An aluminum fitting could easily deform, or its cam arms could snap, sending a heavy, slurry-filled hose whipping violently. A stainless steel fitting is engineered to take that punch.

-

The Deep Freeze: It’s a frigid morning, and the team is coupling hoses with standard nitrile gaskets. The sub-zero temperature has turned the gaskets hard and inflexible. When the system powers up, the stiff gaskets can't create a proper seal. The result is a messy, hazardous, and time-wasting slurry leak.

These examples aren't hypotheticals; they happen. Respecting pressure and temperature ratings isn't just about following the rules—it's about proactive safety. When you choose high-quality stainless steel camlock fittings, you're investing in a system built for the unpredictable nature of hydrovac work, keeping your crew safe and your project on track.

A Field Guide to Camlock Installation and Maintenance

Even the toughest camlock fittings stainless steel need to be handled right to give you peak performance day in and day out. Think of installation as more than just clicking two pieces together; you're laying the groundwork for a safe, efficient shift. A sloppy connection is a wide-open invitation for leaks, pressure loss, and premature wear—the kinds of problems that can bring a high-stakes hydrovac job to a screeching halt.

Proper installation is a quick, three-step dance that’s all about attention to detail. Getting it right ensures every connection is as solid as the fitting itself, stopping little issues from snowballing into major downtime. This discipline is absolutely critical when you're connecting precision tools like The Hydrovac Attachment Tool, where a perfect seal is non-negotiable for powerful, accurate digging.

The Right Way to Install Camlock Fittings

A secure connection doesn’t just happen when you close the arms. It starts a few seconds earlier with a quick inspection that can save you hours of headaches down the road.

-

Inspect and Clean Both Ends: Before you even think about connecting, give both the male adapter and female coupler a quick once-over. Look for any dirt, gravel, or leftover slurry. Debris trapped where the seal happens is the number one cause of leaks. A quick wipe is all it takes.

-

Check the Gasket Seating: The gasket inside the female coupler is the heart of the whole connection. Make sure it’s sitting snugly in its groove, isn't cracked, and hasn't been squashed flat or gone hard from past jobs.

-

Get a Secure, Smooth Lock: Slide the male adapter all the way into the coupler. Then, using firm and even hand pressure, close both cam arms at the same time. They should snap into place. You shouldn't need a hammer or a pry bar—if you do, something's wrong.

A common mistake is thinking tighter is always better. If you have to fight to close the arms, that’s a huge red flag. Forcing it can over-compress the gasket, causing it to fail early, or even bend the arms and ruin the fitting's integrity.

Proactive Maintenance for Maximum Uptime

For hydrovac crews, preventative maintenance isn't just a suggestion—it's what separates a profitable operation from a broken-down one. Regular checks turn your fittings from disposable parts into long-term assets.

Weaving these simple habits into your daily and weekly routines will keep your camlock fittings stainless steel in prime shape and your crew safe. For a deeper dive into building these habits into your workflow, resources on practical safe work procedures are a great place to start.

Daily Checks (Pre-Shift):

- Gasket Integrity: A quick visual check is all it takes. Look for any cracks, tears, or warping. A bad gasket is a guaranteed leak waiting to happen.

- Cleanliness: Make sure all fitting ends are clear of the mud and grime from yesterday's job.

- Arm Movement: Flip the cam arms open and closed. They should move smoothly without catching or feeling stiff.

Weekly Inspections:

- Wear on Arms and Pins: Take a closer look at the cam arms and the pins they pivot on. If you see significant wear or any bending, it’s a sign the connection could fail under pressure.

- Corrosion Check: While stainless steel is tough, it's not invincible. Scan for any pitting or weird discoloration, especially if you’re working in highly corrosive soil or with harsh chemicals.

- Hose Connection Security: Wiggle the hose where it meets the fitting. Make sure the shank is still clamped down tight. The connection is only as strong as its weakest link, and that includes the hose clamp. For more on this, see our guide on the right vacuum hose clamps.

By making these quick inspections a habit, you empower your crew to spot trouble before it starts. This proactive mindset doesn't just make your equipment last longer; it builds a culture of safety and reliability on every single job site.

See It In Action: The 2.5" Hydrovac Attachment

All the talk about grades, types, and pressure ratings for camlock fittings stainless steel is great, but it really clicks when you see how they perform in the field. This is where a specialized tool can take a messy, time-consuming job and make it clean, fast, and professional. For any hydrovac crew, the right gear is often the only thing standing between a productive day and a frustrating one. The Hydrovac Attachment is the hydrovac industry's premier solution for effective digging purposes.

Enter the 2.5" Hydrovac Attachment. It’s designed to turn a standard pressure washer and wet-vac into a powerful, surgical digging system. The whole setup relies on a perfect, leak-free connection, which is exactly why getting the right stainless steel camlocks is so critical. They are the lynchpin that makes this whole system work flawlessly on the job site.

A Simple Setup for Serious Performance

One of the best things about a camlock system is its speed, and connecting the Hydrovac Attachment is a perfect example. You can be up and running in just a couple of minutes.

- Hook Up Your Wet-Vac: The tool's base connector slides right onto a standard 2.5-inch wet-vac hose and is locked down with a heavy-duty hose clamp.

- Connect Your Pressure Washer: Your pressure washer wand fits neatly into the tool, where the nozzle cap holds it tight.

- Link to Your Truck: Using the right stainless steel camlock adapters, your 2.5-inch hose connects securely to your main hydrovac vacuum hose.

This quick, three-step process, made possible by tough camlock fittings stainless steel, creates a self-contained system. High-pressure water is aimed with precision, and the slurry it creates is immediately pulled into the vacuum stream. The difference this makes compared to the old way of doing things is night and day.

The Before-and-After Difference

Think about the old way of potholing. You’ve got one operator trying to aim a high-pressure wand into a hole while wrestling a separate, bulky vacuum tube next to it. It almost always ends the same way: a chaotic storm of mud, water, and rocks flying everywhere. This constant splashback covers the operator, kills visibility, and turns the work area into a slippery, hazardous mess.

Now, imagine that same job with the Hydrovac Attachment Tool.

The operator holds a single, lightweight tool that directs water and suction to the exact same point. Splashback is virtually gone. Visibility stays crystal clear, which is crucial for digging around sensitive utilities. The work area remains clean, and the job gets done faster and with a much more professional finish.

This controlled approach is a game-changer. Whether you're daylighting utilities, trenching for new lines, or just clearing out stubborn clogs, the tool gives you a level of control that traditional methods simply can't offer. By integrating with your existing equipment using the strength and reliability of stainless steel camlocks, it makes your hydrovac work safer, cleaner, and a whole lot more efficient.

Answering Your Top Questions About Stainless Steel Camlocks

Even after you get the hang of stainless steel camlocks, questions always pop up out on a job site. Let's tackle a few of the most common ones we hear from hydrovac crews so you can make the right call with confidence.

Can You Mix Stainless Steel and Aluminum Camlocks?

This is a big one. While you technically can connect them, mixing stainless steel with other metals like aluminum is a recipe for disaster in hydrovac work. It kicks off something called galvanic corrosion, where the weaker metal—the aluminum—basically sacrifices itself and corrodes away at a much faster rate.

The connection gets weak, the seal fails, and the risk of a blowout under pressure goes through the roof. Stick to the golden rule: steel on steel. It's the only way to guarantee a safe, durable connection.

How Often Should Gaskets Be Replaced?

There's no single answer here, as a gasket's lifespan really depends on what you're sucking up, the temperatures you're working in, and how often the gear is used. A good rule of thumb is to give your gaskets a quick visual check every single day. Look for any cracking, warping, or if they just feel brittle and hard.

For crews running their trucks daily, it's smart to just swap them out every 3 to 6 months as a preventative measure. A handful of spare gaskets in the truck is cheap insurance against the downtime a single failed seal can cause.

Are Stainless Camlocks Overkill for Smaller Jobs?

Not at all. The toughness and reliability of stainless steel are just as important on a small residential dig as they are on a massive industrial site. They stand up to the abrasion from dirt and rocks, handle being dropped or knocked around, and give you that leak-free, professional connection every time.

Think about it this way: for a precision tool like The Hydrovac Attachment, using anything less than stainless steel just doesn't make sense. It’s about building a solid, dependable system that you can trust to perform day in and day out. That quality protects your reputation, your gear, and ensures you're digging effectively, no matter the size of the job.

Ready to make your hydrovac operations cleaner, safer, and more efficient? Equip your crew with the Hydrovac Attachment and experience the difference a purpose-built tool can make.