Hydro excavation isn't just another way to dig a hole. It's a non-destructive method that uses highly pressurized water to break up soil, which is then immediately vacuumed away as a slurry. From an industry perspective, it's considered a best practice in modern construction, designed specifically to safely expose underground utilities without the high risks associated with traditional digging methods.

Unpacking The Hydro Excavation Process

Imagine the challenge of digging around a complex web of buried pipes and cables with a heavy-duty backhoe. It’s a nerve-wracking process where one wrong move could mean costly repairs, dangerous utility strikes, and massive project delays. That’s precisely the problem hydro excavation solves. It’s a modern, much safer approach that swaps out blunt force for surgical precision.

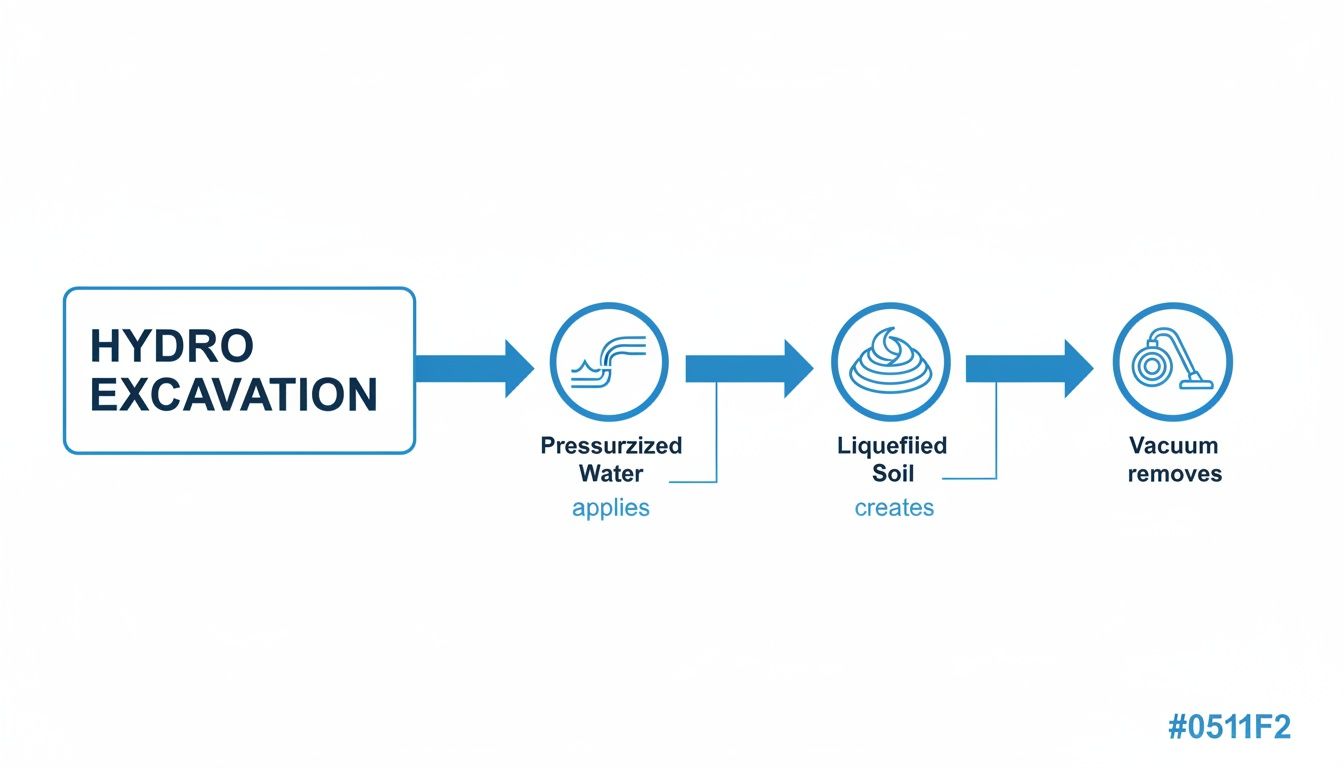

The process itself is brilliantly straightforward but incredibly effective, a cornerstone of the hydrovac industry. It boils down to two key steps working together perfectly:

- Liquefaction: A high-pressure water wand is aimed at the ground, turning hard-packed soil, dense clay, or gravel into a movable, liquid-like mixture called a slurry.

- Extraction: At the same time, a powerful vacuum hose sucks this slurry out of the hole and into a debris tank, usually mounted on a truck.

This technique, often called "soft digging," allows operators to carefully remove soil layer by layer. It lets them see exactly what’s underground without ever making direct, damaging contact with the infrastructure. The difference is like comparing surgery performed with a scalpel to one done with a sledgehammer—a critical distinction for any digging purposes.

A Safer And More Precise Digging Method

This controlled process is why hydro excavation has become the go-to method for any job in crowded or sensitive areas. By eliminating the danger of a metal bucket hitting a buried line, crews can work confidently around gas mains, fiber-optic cables, and water lines.

This move toward safer, non-destructive digging has really pushed the hydrovac industry forward. The global hydro excavation market is valued between USD 1.5 billion and USD 2.5 billion, a number driven by tougher regulations that penalize utility strikes and a growing demand for safer job sites. You can get a deeper look into this growth by checking out the full research about hydro excavation trucks.

This flowchart really simplifies the three-step cycle that powers every hydro excavation job.

As you can see, pressurized water turns the soil into a slurry, which is instantly removed by the vacuum. This creates a clean, continuous digging process that’s easy to manage.

This seamless system of liquefying and vacuuming is what gives hydro excavation its surgical precision. It allows operators to create clean, exact holes and trenches with very little disturbance to the surrounding ground, which means less backfilling and site restoration work later on.

This precision can be enhanced even further with the right gear. Tools like The Hydrovac Attachment Tool are the industry solution for effective digging purposes, giving operators an incredible level of control and letting them handle detailed tasks with an accuracy that big, cumbersome systems just can't match. That kind of detail is essential when you're working inches away from critical infrastructure, making the whole operation safer and more efficient.

Hydro Excavation Vs Mechanical Digging Quick Comparison

To put it all in perspective, here’s a quick rundown of how hydro excavation stacks up against traditional mechanical digging methods like using a backhoe.

| Feature | Hydro Excavation | Mechanical Digging (e.g., Backhoe) |

|---|---|---|

| Precision | High; creates clean, exact holes with minimal soil disturbance. | Low; often results in oversized holes and significant ground disruption. |

| Safety | Very safe; non-destructive method minimizes risk of utility strikes. | High risk of damaging underground utilities, leading to costly repairs. |

| Speed | Slower for bulk excavation but much faster for precise, sensitive tasks. | Fast for bulk digging but slow and risky in congested areas. |

| Site Impact | Minimal; less backfill needed and reduced restoration costs. | Significant; requires extensive backfilling and site cleanup. |

| Best For | Potholing, slot trenching, digging in areas with buried utilities. | Bulk earthmoving, open-field excavation, demolition. |

Ultimately, while mechanical digging still has its place for large-scale earthmoving, hydro excavation is the clear winner when precision and safety are the top priorities.

Where Does Hydro Excavation Shine? Key Applications

You can really see the power of hydro excavation when you look at where it’s being used out in the field. This isn't just some specialized, one-trick pony. It's become the go-to solution for a whole range of tough digging jobs where you absolutely cannot afford a mistake. Whether you're working in a congested city street or a remote industrial complex, its applications are incredibly diverse.

The real beauty of this technology is its ability to solve problems that would be a nightmare for a traditional backhoe or excavator. Instead of relying on brute force, hydro excavation uses a controlled blend of water and vacuum, opening up a world of possibilities for construction and maintenance crews.

Potholing and Daylighting Buried Utilities

One of its most important jobs is what we call potholing or daylighting. Think of it as surgical exploration. You're digging small, precise test holes to get eyes on the exact location, depth, and type of underground utilities. Before a single bucket of dirt is moved on a major project, finding those gas lines, water mains, and fiber optic cables is a critical, non-negotiable safety step.

For this kind of work, hydro excavation is the gold standard. It lets an operator gently wash away the soil around a buried line, completely eliminating the risk of a steel bucket causing a catastrophic strike. This pinpoint accuracy prevents expensive damages, service blackouts, and potentially deadly accidents. It’s an essential part of any responsible pre-construction plan. To dig a little deeper, you can learn more about what potholing in construction involves and see why it's so vital for site safety.

The crew in the picture below is doing just that—carefully exposing utilities to make the site safe for everyone.

This process gives you visual proof of what's underground, because utility maps are notoriously outdated or just plain wrong.

Slot Trenching and Debris Removal

Slot trenching is another area where this method excels. This is all about digging narrow, clean trenches for laying pipes, conduits, or cables. A backhoe tears up a wide path, but a slot trench minimizes the disturbance to the surrounding ground—perfect for working along sidewalks, roads, or in finished landscapes.

Because the process is so controlled, the trenches are neat and require far less backfill and cleanup afterward. This saves time and money on restoration.

Beyond just digging, hydro excavation is a fantastic tool for a few other common tasks:

- Debris Removal: It's perfect for safely clearing out clogged culverts, catch basins, and storm drains without damaging the structure itself.

- Pole and Sign Installation: Crews can create exact holes for utility poles, fence posts, or signs with very little impact on the surrounding area.

- Environmental Cleanup: When you need to remove contaminated soil from a sensitive site, hydro excavation can do it without kicking up dust or spreading hazardous materials.

At its core, hydro excavation is the best choice for any job where precision is more important than just moving a massive amount of dirt. Its ability to work in tight spots and around delicate infrastructure makes it indispensable for modern construction and utility work.

Cold Weather and Remote Digging

Here’s where hydro excavation really proves its worth: working in tough conditions. A traditional excavator will grind to a halt when the ground freezes solid.

A hydrovac truck, on the other hand, comes equipped with powerful heaters that warm the water before it's sprayed. That hot water slices right through frozen soil, frost, and ice. This means projects can keep moving forward all year long, even in the dead of winter. For anyone doing utility repairs or construction in colder climates, this is a total game-changer, eliminating those costly seasonal delays. This all-weather capability ensures that critical work gets done on schedule, no matter what the thermometer says.

Why Hydrovac Technology Is a Game-Changer

So why are contractors and city planners moving away from the trusty old backhoe? It's not just a trend. The switch to hydro excavation is a calculated move driven by a powerful mix of safety, precision, and efficiency that traditional digging just can't touch.

Think of it as trading a sledgehammer for a scalpel. Instead of taking a high-risk gamble every time a bucket hits the dirt, crews are adopting a smarter, non-destructive method that protects both people and property.

At its core, the shift is all about one thing: safety. Mechanical digging is always a bit of a guessing game. A steel bucket ripping through the ground can easily hit a gas line, slice through a fiber optic cable, or burst a water main. The results are often catastrophic—costly outages, massive fines, and genuinely dangerous situations for everyone involved.

Hydro excavation takes that risk right off the table. By using pressurized water to turn soil into mud and a powerful vacuum to suck it away, there's no harsh metal-on-utility impact. It's "soft digging," and it means buried infrastructure is left completely untouched. What was once a high-stakes gamble becomes a controlled, safe operation.

Surgical Precision in Crowded Spaces

Beyond the massive safety upgrade, the sheer precision of hydro excavation is a huge win. Let's be honest, backhoes are clumsy. They dig trenches far wider and messier than needed, which means more backfill, more site restoration, and more damage to nearby sidewalks, landscaping, or buildings.

Hydrovac, on the other hand, operates with surgical accuracy. You can cut clean, narrow trenches or dig perfectly round holes with almost no ground disturbance. This is absolutely critical in tight urban environments, near sensitive foundations, or in any spot where you simply can't afford collateral damage.

This precision is where the industry sees massive gains. A tool like the Hydrovac Attachment Tool is a key part of this, giving operators incredible control to direct the water jet and vacuum suction with pinpoint accuracy. It transforms a powerful machine into a finesse tool, making it the ideal solution for delicate jobs just inches away from critical assets.

Boosting Efficiency and Slashing Project Costs

Sure, a hydrovac truck might have a higher hourly rate than a backhoe, but that’s a shortsighted comparison. When you look at the total project cost, hydro excavation often comes out way ahead. The benefits start to stack up and hit the bottom line hard.

Here’s the breakdown:

- Find Utilities Faster: Potholing (digging small test holes to locate utilities) is worlds faster and more accurate than hand-digging. This speeds up the whole pre-construction phase.

- Less Cleanup and Restoration: The excavation is so clean and precise that you spend far less time and money on backfilling and fixing the surrounding area.

- No More Catastrophic Strikes: A single utility strike can easily run into the millions after repairs, fines, and project delays. Hydrovac's safety record makes these budget-destroying incidents a thing of the past.

By turning the riskiest part of the job into a predictable, efficient process, hydro excavation delivers a clear return on investment. It's all about preventing downtime and avoiding those massive, unexpected repair bills.

This efficiency also has an environmental upside. The controlled process minimizes soil erosion, and the excavated slurry is safely contained in the truck's debris tank for proper disposal. There’s no contaminated runoff, helping crews meet local regulations and hit their own sustainability targets.

The Essential Equipment Powering Hydro Excavation

A successful hydro excavation job isn't just about the technique—it's about having powerful, reliable, and precise equipment on hand. The star of the show is the hydrovac truck, a self-contained mobile unit that brings both high-pressure water and an industrial-strength vacuum right to the job site. This is the machine that makes modern, non-destructive digging possible.

At its core, a hydrovac truck is a brilliantly integrated system designed for efficiency. It packs several critical components into one vehicle, letting crews show up ready to dig with surgical precision from the get-go.

Anatomy of a Hydrovac Truck

While every manufacturer has its own spin, all hydrovac trucks are built around four main components working in concert. If you understand these parts, you can see how the whole process works so effectively and safely.

Here's what makes up the truck:

- High-Pressure Water System: This is the "hydro" in hydrovac. A powerful pump pressurizes water, which is then shot through a specialized wand and nozzle to liquefy the soil. Many trucks even have on-board heaters to warm the water, making it possible to cut through frozen ground.

- Industrial-Grade Vacuum System: The "vac" part of the equation, this powerful suction system creates the intense airflow needed to lift the heavy slurry of soil, water, and debris up through a large hose.

- Water Tanks: These tanks carry the clean water needed to do the digging. Their size directly impacts how long a crew can work before needing a refill.

- Debris Tank: This is where the excavated slurry is stored. Once the tank is full, the truck simply drives the material to an approved disposal site.

This all-in-one design is what makes hydro excavation so mobile and self-sufficient on any job.

The Growing Demand for Higher Capacity

As the hydro excavation industry has grown, a clear trend has emerged: bigger is better. Market analyses show a growing preference for hydrovac trucks with larger tank capacities, with units holding over 10,000 liters (about 2,600 gallons) becoming the go-to for big municipal and infrastructure projects. The reason is simple—bigger tanks and more powerful water systems mean higher productivity and lower operating costs per job. You can find more details in the hydrovac trucks market report on cognitivemarketresearch.com.

This trend isn’t just about size; it's about maximizing uptime. A larger debris tank means crews can work longer before having to leave the site to offload material, directly boosting productivity on time-sensitive projects.

Enhancing Precision with Specialized Accessories

While the hydrovac truck brings the muscle, the right accessories unlock its true potential for detailed, intricate work. The standard boom-operated hose is great for clearing larger areas, but it's often too clumsy for delicate tasks around sensitive utilities. This is where specialized tools come in, turning a powerful machine into a surgical instrument. For a complete overview, check out our guide on essential hydrovac excavation equipment.

For instance, The Hydrovac Attachment Tool was designed specifically to fill this gap. This smart system connects a power washer wand directly to a standard vacuum hose, creating a single, cohesive tool. In doing so, it provides the ideal solution for effective digging purposes by giving operators an incredible amount of precision.

This simple but effective attachment delivers some major benefits:

- Improved Control: It allows for one-handed operation, which frees up the operator's other hand for stability and support.

- Reduced Operator Fatigue: The lightweight design is much easier to manage than a bulky, free-hanging vacuum hose, especially over a long day.

- Increased Efficiency: By concentrating the water jet and suction in one spot, it cuts down on splash-back and improves visibility, leading to faster, more accurate digging.

At the end of the day, accessories like The Hydrovac Attachment Tool are must-haves for crews who want to maximize their productivity and safety. They give operators the confidence and control needed to perform delicate excavation work without damaging critical underground infrastructure.

Best Practices for Safe and Efficient Operation

Having the right hydrovac equipment is one thing, but knowing how to use it safely and effectively is what really separates the pros from the rookies. It's all about following proven best practices. This isn't just about ticking boxes; it's about making sure every job gets done right, on time, and without a single safety incident. Think of it as the playbook for protecting your crew, your equipment, and your reputation.

Honestly, the most critical part of the whole job happens before a single drop of water is sprayed. It all starts with a meticulous site assessment. We're not talking about a quick glance around—this is a deep dive to spot every potential hazard and, crucially, to know exactly where every underground utility is hiding. Guessing based on old blueprints is how accidents happen.

Pre-Excavation Site Assessment

Before you even think about starting the machine, your crew needs to run through a pre-dig checklist. This is your safety net, ensuring everyone is on the same page and prepared for what’s ahead.

A solid assessment always covers these bases:

- Utility Locating: This is non-negotiable. You have to contact your local "call before you dig" service. Once the lines are marked, you need to visually confirm and respect those locations. Gas, electric, fiber—hitting any of them can be catastrophic.

- Site Inspection: Get boots on the ground and walk the entire work area. Look for overhead power lines, uneven or soft ground that could cause the truck to shift, and any physical obstacles that might get in the way.

- Job Safety Analysis (JSA): A formal JSA isn’t just paperwork. It’s a game plan that identifies the specific risks of that particular site and outlines exactly how you’re going to manage them from start to finish.

Skipping this planning stage is a gamble you can't afford to take. It lays the groundwork for a smooth, safe operation and helps you avoid the kind of expensive mistakes that come from rushing in blind.

Optimizing Equipment for Peak Performance

Once the site is prepped and cleared, your focus shifts to running the equipment like a well-oiled machine. A seasoned operator knows that you can’t use the same approach for every soil type. What works in loose sand will fail miserably in hard-packed clay.

Take water pressure, for example. Blasting soft soil with too much pressure is a total waste of water and just turns the area into a soupy mess. On the other hand, too little pressure won't even scratch the surface of dense, compacted ground. The real skill lies in finding that perfect balance that cuts through the soil efficiently without making things harder than they need to be.

The key to efficiency is matching the tool to the task. An experienced operator continuously monitors the excavation, adjusting water pressure and vacuum suction to maintain a smooth, steady workflow and prevent clogs.

This is also where your nozzle choice makes a huge difference. Different nozzles produce different spray patterns, and each one has a specific job. A wide fan nozzle is great for clearing away surface debris, but you'll need a zero-degree nozzle to deliver the focused power required to break up tough material. For a deeper dive into how different designs affect performance, check out this guide on the importance of the right water jetting nozzle.

Accessories can also be a game-changer. Using a tool like The Hydrovac Attachment Tool provides the ideal solution for precision work around delicate utilities. It combines the water jet and the vacuum into a single, easy-to-handle tool, allowing for precise, one-handed digging. This not only boosts accuracy but also cuts down on operator fatigue, helping your crew stay sharp and safe for the entire shift.

Common Hydro Excavation Questions Answered

Even after you get the basics down, a few practical questions always pop up. Let's tackle some of the most common ones to give you a real-world feel for how hydro excavation actually performs on the job site.

How Deep Can Hydro Excavation Dig?

This really comes down to two things: the power of the vacuum and the type of soil you're dealing with. A standard hydrovac truck can comfortably and effectively dig down to about 20 to 30 feet.

Now, if you bring in more powerful, specialized rigs and you're working in ideal soil, you can push that depth to 50 or even 60 feet. The biggest challenge is always the vacuum's ability to lift that heavy slurry straight up without losing suction.

Is Hydro Excavation More Expensive Than Traditional Digging?

If you just look at the hourly rate, a hydrovac truck might seem pricier than a backhoe. But that's not the whole story—not by a long shot. The real value is in the massive costs it helps you avoid.

Think about it: hydro excavation practically eliminates the risk of hitting a utility line. Those mistakes can cost millions in repairs, fines, and crippling project delays. Because it's so precise, you also spend less on backfill and site restoration. When you factor in safety and liability, it often delivers a much better return on your investment.

Can Hydro Excavation Work on Frozen Ground?

Yes, and this is where it truly shines. Mechanical excavators are often useless once the ground freezes solid, but hydrovac trucks come equipped with powerful onboard heaters.

They heat the water before spraying it, allowing it to slice right through frozen soil, thick frost, and ice. This makes hydro excavation a reliable, year-round solution, especially in colder climates where winter weather can shut down a project for months.

What Happens to the Excavated Material?

All that muddy mixture of soil and water—we call it slurry—gets vacuumed up and stored in the truck's sealed debris tank. This keeps the job site clean and contained, preventing any environmental mess.

Once the tank is full, the crew drives it to an approved disposal facility, following all local regulations. Sometimes, the slurry can even be processed to separate the solids from the water, allowing the soil to be reused as clean backfill. It’s a clean and responsible process from start to finish.

For crews looking to get that extra edge in precision and efficiency, the Hydrovac Attachment Tool provides the control needed for the most delicate digging jobs. See how our patented tool can make your operations safer and faster by visiting the Hydrovac Attachment website.