If you've spent any time on a hydrovac truck, you know that the smallest parts can cause the biggest headaches. A threaded hose connector is a perfect example. It’s the simple fitting that screws together to join hoses, creating the seal that makes the whole system work. But for us in the hydrovac industry, it's the critical link that determines whether a job goes smoothly or turns into a muddy, frustrating mess.

A solid connection is everything. It prevents leaks, maintains suction, and ultimately dictates how safe, precise, and efficient your digging is. When you're exposing delicate utilities, a reliable connection isn't a luxury—it's a necessity.

Why Getting Threaded Connections Right is a Big Deal in Hydrovac

In the world of hydrovac, precision is everything. We measure success by the inch, and any downtime or cleanup from a bad connection hits you right in the wallet. A loose or mismatched threaded hose connector isn't just a minor drip; it's a real operational risk.

Think about it: slurry splashing everywhere, a sudden loss of suction, and potential safety hazards on site. The whole point of a hydrovac system is to create a sealed, powerful pathway for high-pressure water and industrial-strength vacuum. A weak connection at any point completely undermines that, turning what should be a controlled excavation into a messy battle with your own gear.

The True Cost of a Bad Connection

When a threaded connector gives up on a hydrovac job, the fallout spreads fast. You’re stopping work to fix a leak, which kills your schedule and drives up labor costs. Even worse, that uncontrolled spray can blind you to what you're digging, making it impossible to safely expose sensitive utilities like gas lines or fiber optics.

This is exactly why specialized gear like The Hydrovac Attachment Tool exists. It was built to solve this exact problem, standardizing the link between a power washer wand and a standard 2.5-inch wet-vac hose. It takes a known weak point and turns it into a source of strength, creating a single, reliable threaded system you can count on for effective digging purposes. That means you can focus on digging, not on fighting your equipment.

The integrity of your whole excavation hinges on the quality of its smallest parts. A secure threaded connection is the bedrock of safe potholing, efficient trenching, and accurate utility locating.

It's no surprise that the demand for better, more reliable components is on the rise. The global market for hose connectors is projected to grow from USD 12,450.75 million to USD 19,560.40 million by 2032. That's a huge jump, and it's driven by industries like hydrovac, construction, and utilities who need parts that won't fail under pressure. Every little improvement in connector technology directly boosts uptime and safety on thousands of job sites every single day. Learn more about the hose connector market outlook.

How to Identify Thread Types and Sizes in the Field

Nothing kills momentum on a job site faster than showing up with mismatched connectors. It's a classic rookie mistake, and for hydrovac crews, getting the hose connector threaded right the first time isn't just a suggestion—it's essential. This isn't about memorizing textbook charts; it's about being able to look at a fitting in the dirt and know exactly what you're dealing with.

You're going to run into a few usual suspects out there: NPT (National Pipe Taper), BSPT (British Standard Pipe Taper), and JIC (Joint Industry Council) are the big ones. Each has its own distinct design. NPT threads, for instance, are tapered, meaning they get slightly narrower toward the end. This taper is what creates the seal when you tighten them. You can often spot that subtle cone shape just by eye.

Visual Cues and Quick Field Tests

Your eyes are your best first tool. A quick visual inspection can tell you a lot. Does the thread visibly narrow at the end? That's a tapered thread. Does it look like a perfectly straight cylinder? That's parallel. Trying to force a parallel male fitting into a tapered female port is a fast track to stripped threads and a leak you'll never fix.

If you’re not 100% sure, grab a couple of simple tools from the truck:

- Thread Pitch Gauge: This handy little tool looks like a set of keys. You just flip through the "leaves" until you find one that sits perfectly in the fitting's threads. That tells you the pitch, or threads per inch.

- Calipers: A good set of digital or dial calipers is invaluable. Measure the outside diameter of a male fitting or the inside of a female one. This confirms the size, like whether you're holding a 3/4-inch or 1-inch NPT.

Knowing the size is only half the battle. You absolutely have to know the type to get a proper seal. For a deeper dive, understanding different thread types can give you a solid foundation on how these systems actually work.

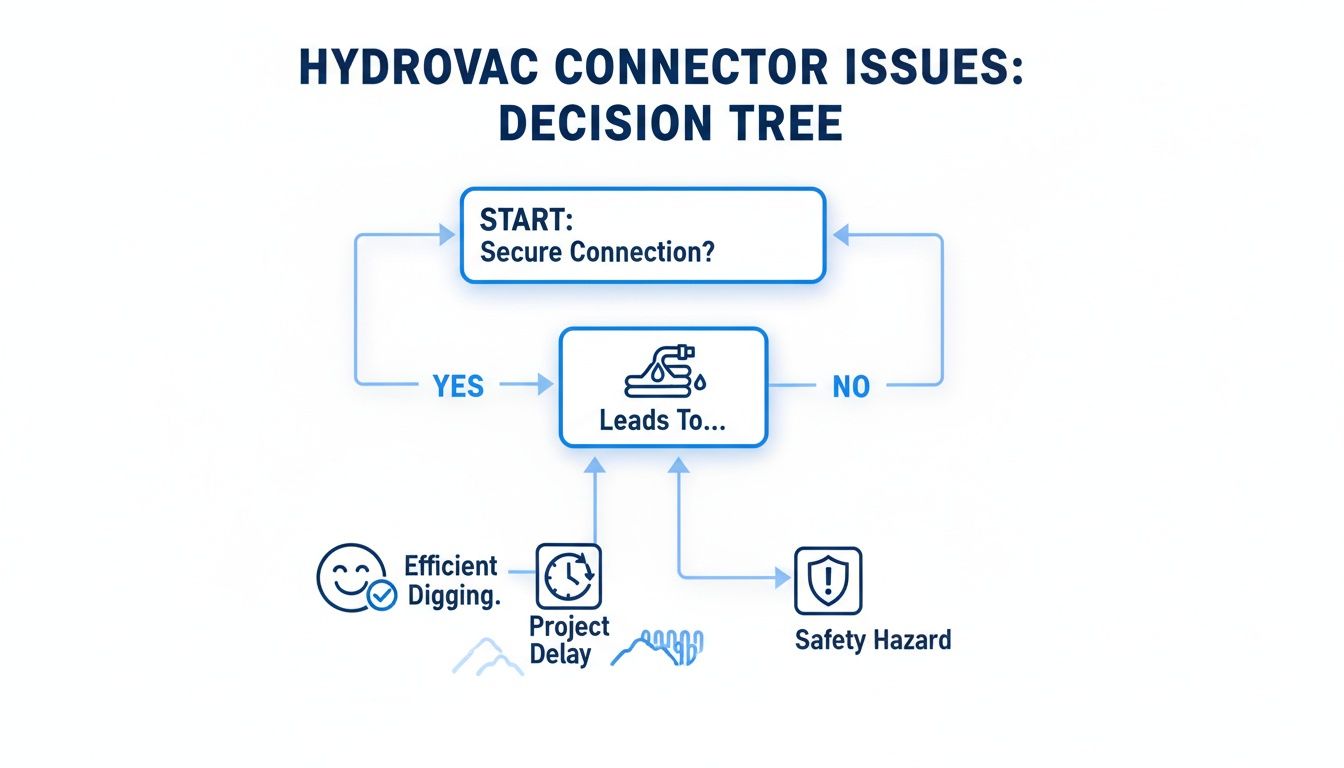

The diagram below breaks down just how much is riding on getting this right. A solid connection means a smooth job, while a bad one is a recipe for disaster.

As you can see, a secure hose connector threaded properly leads directly to efficient digging. On the flip side, a weak or incorrect connection is a direct path to project delays and serious safety hazards.

Common Thread Types for Hydrovac Equipment

To make things easier in the field, here's a quick cheat sheet for the most common threads you'll find on hydrovac and power washing gear.

| Thread Type | Key Identifier | Seal Method | Common Application |

|---|---|---|---|

| NPT | Tapered threads | Thread deformation (sealant needed) | General-purpose water/air lines |

| BSPT | Tapered threads, different pitch/angle | Thread deformation (sealant needed) | Often on European equipment |

| JIC | 37-degree flared seating surface | Metal-to-metal seal on the flare | High-pressure hydraulic systems |

This table is just a starting point, but it covers what you’ll see 90% of the time. Getting familiar with these will save you countless headaches.

Standardization in the Hydrovac Industry

With massive infrastructure projects across North America, the demand for reliable hydrovac equipment is exploding. The regional market for hydraulic fluid connectors was valued at US$ 5.8 billion and is projected to skyrocket to US$ 13.4 billion by 2035. This boom is forcing the industry to adopt more rugged, standardized connectors that can handle the dual punishment of high-pressure water and abrasive slurry. That makes identifying them correctly more critical than ever.

A mismatched thread is more than an inconvenience; it’s a weak link that compromises the power and safety of your entire hydrovac system. Taking a moment to verify a connection saves hours of frustration.

This is exactly why tools like The Hydrovac Attachment were developed to work flawlessly with standard 2.5-inch wet-vac hoses. It standardizes the connection point between your high-pressure wand and the vacuum hose, taking all the guesswork out of the equation. No more hunting for oddball adapters or fighting with leaky fittings. Your crew can just hook up and get back to digging, making it the ideal solution for effective hydro-excavation.

While we've focused on threaded connectors here, it's also smart to know about other systems. For example, it’s worth learning more about how camlock fittings work, as you'll often see them used in different parts of a hydrovac setup.

Achieving a Perfect Leak-Proof Seal Every Time

Getting the threads to match is just the start. The real test of any hose connector threaded system is whether it can create and maintain a perfect, leak-proof seal out in the field. Even a small drip can quickly turn into a major problem—pressure loss, messy splashback, and a drop in suction power that kills your efficiency on the job.

A solid, durable seal is what truly completes the connection, making sure all the force from your water jet and vacuum is concentrated right where you need it. This is where the right materials and proper technique come into play, turning a simple connection into a tough, field-ready joint.

Choosing the Right Sealing Method

When it comes to hydrovac work, you'll generally use one of two methods to get a leak-free seal on tapered threads: thread seal tape or liquid thread sealant. Each has its strengths.

- Teflon Tape: This is the classic choice for most high-pressure water lines. The key is to apply it correctly. Always wrap the tape in the same direction the male fitting will turn when you tighten it—usually clockwise. This simple trick keeps the tape from bunching up or shredding. Three to four wraps are usually enough for a solid seal.

- Liquid Thread Sealant: This stuff is fantastic for vacuum-side connections or anywhere with a lot of vibration. Liquid sealants work by filling the tiny gaps between threads and then curing to create a flexible yet incredibly strong seal. They hold up great against the abrasive slurry that hydrovac systems are constantly pulling through.

- O-Rings: You’ll typically find these in quick-disconnect fittings, where they create a seal through compression. Just make sure the O-ring is seated perfectly in its groove. A pinched or twisted O-ring is one of the most common reasons for a sudden leak.

The same core principles apply here as they do in complex plumbing. Understanding professional installation techniques for leak-free connections is crucial for preventing leaks that can cost you time and money.

The Dangers of Over-Tightening

It’s a natural instinct to think "tighter is better," but over-tightening is one of the fastest ways to break your gear. When you crank down too hard on a hose connector threaded fitting, you can strip the threads, crack the housing, or warp the sealing surfaces. You've just guaranteed a leak.

The real goal is to tighten until the connection feels snug, then let the sealant or tape do its job.

This is especially important when you’re working with tools like The Hydrovac Attachment. While its industrial-grade polymer body is built to be tough, applying way too much torque can compromise the connection point. Proper tightening ensures the attachment and your 2.5-inch wet-vac hose become a single, robust system that can handle demanding field conditions without failing. This tool is the premier solution for effective hydro-excavation.

A proper seal isn’t about brute force; it’s about the correct application of the right sealing material combined with the right amount of torque. This balance is what creates a connection you can trust.

Making the Connection with The Hydrovac Attachment Tool

Out in the field, the last thing you want to do is waste time wrestling with mismatched fittings. Getting your gear connected quickly and securely is everything. Once you’ve got the right hose connector threaded type picked out and you know your seal is solid, it's time to assemble the whole rig. This is where a smartly designed tool really proves its worth, turning what could be a frustrating hassle into a fast, repeatable task that gets your crew digging sooner.

The Hydrovac Attachment Tool was born from this exact need. It was designed from the ground up to create a rock-solid link between a high-pressure wand and a standard 2.5-inch wet-vac hose, solving one of the most common points of failure we see on the job. Its simple, three-part assembly makes it the practical solution for effective digging.

A Dead-Simple, Three-Part Assembly

The beauty of this setup is its simplicity. You can forget about digging through a bucket of random adapters or fighting with threads that just won't line up. Anyone on the crew can master this in a couple of minutes.

-

First, the Base Connector: Just slide the main base connector onto the end of your 2.5-inch wet-vac hose. It's machined for a snug fit, giving you a solid foundation right from the start.

-

Next, the Clamp: Position the heavy-duty hose clamp over the base connector and crank it down. This isn't a friction fit; it's a mechanical lock that ensures the attachment won't budge or twist, even when the hydrovac truck is pulling serious suction.

-

Finally, the Wand and Nozzle Cap: The last step is just threading your power washer wand into the nozzle cap. The threads are standardized, so you get a perfect, leak-proof seal every single time. It’s ready for high-pressure work in seconds.

This design just takes the guesswork out of it. You’re not just connecting pieces; you’re creating a single, integrated tool built for the tough stuff.

How It Works on a Real Job Site

Think about the last time you were potholing to locate a delicate fiber optic line. Precision is everything in that situation. With a secure hose connector threaded system like the one on The Hydrovac Attachment Tool, you gain an incredible amount of control. The water jet and the vacuum work together perfectly, which cuts down on slurry splashback and keeps your view of the utility clear. That means you can work closer and with more confidence, seriously reducing the chance of a costly strike.

Or picture trenching for irrigation lines in a small residential yard. A full-size hydrovac lance can be overkill and make a huge mess. This attachment lets you create a focused, almost surgical excavation zone. The debris gets sucked away instantly, keeping the customer's property clean and saving you a ton of time on cleanup later. As a solution for effective digging, this tool is unmatched.

The Hydrovac Attachment Tool standardizes the most critical connection point in your setup. This simple yet robust design enhances control, boosts efficiency, and ensures a safer, cleaner job site every single time.

This move toward reliable, integrated systems is part of a bigger industry trend. The global market for industrial hoses and fittings is projected to reach about USD 23.77 billion by 2030. While quick-connects are popular, the real innovation is happening in hybrid solutions like this one, where a rugged, threaded base supports quick-change nozzles. That focus on creating efficient, leak-proof connections is becoming the new standard for modern excavation.

At the end of the day, a seamless installation process means your crew spends less time fighting with gear and more time actually working. With a connection you can trust, you can tackle anything from exposing utilities to cleaning out stubborn blockages with more speed and precision.

Maintenance and Troubleshooting for Your Threaded Connectors

Even the toughest gear in the hydrovac industry takes a beating. Proper care is what separates equipment that lasts a season from the stuff that lasts a career, and this is especially true for your hose connector threaded system. It's a simple part, but dirt, grit, and constant vibration can cause a quick failure if you're not paying attention.

A little bit of consistent maintenance goes a long way. It not only keeps your connectors in good shape but also makes sure your Hydrovac Attachment Tool works reliably on every single job. Taking a few minutes for these simple habits can save you from expensive downtime and keep your operations running without a hitch.

Pre-Use Inspection Checklist

Before you even start the truck, get in the habit of doing a quick visual check. It might seem small, but this one routine can save you hours of headaches later by catching a problem before it becomes a full-blown failure on site.

Make this a non-negotiable part of your daily walk-around. Here’s exactly what to look for:

- Stripped or Damaged Threads: Run your finger gently over the male threads. Do you feel any flat spots, sharp burrs, or the tell-tale signs of cross-threading? If so, that fitting is compromised. Trying to force a connection will only make it worse.

- Cracked Fittings: Give the body of the connector a close look. Pay special attention to the base of the threads, which is where most of the stress is concentrated. If you see any cracks, no matter how small, that fitting needs to be replaced immediately. It's a blowout waiting to happen.

- Excessive Dirt or Debris: Slurry and mud love to cake up inside female threads. This gunk not only prevents a tight seal but is also the number one cause of cross-threading. Always have a wire brush and a rag handy to clean them out before you connect anything.

A clean thread is a healthy thread. Seriously, taking just 30 seconds to wipe down and inspect your connectors before each use is the single most effective thing you can do to prevent leaks and premature wear.

Common Field Problems and How to Fix Them

Let's be realistic—even with perfect maintenance, things can go wrong in the field. The key is knowing how to handle these common issues quickly so you can minimize delays and get back to work.

What to Do with a Leaking Connector

First rule: never, ever try to tighten a leaking fitting while the system is under pressure. It’s a huge safety risk. Always depressurize the line completely.

Once it's safe, take the connection apart and look closely at the threads and whatever sealant you used. Nine times out of ten, the problem is shredded Teflon tape or a nicked or flattened O-ring. Clean every bit of the old stuff off the threads, apply fresh sealant, and then reassemble it properly.

How to Loosen a Seized Fitting

Fittings can get stuck from corrosion, being overtightened, or just from grit. Before you reach for a bigger wrench, spray it with a good penetrating oil and give it some time to work its way in.

If it's still locked up, the trick is to use two wrenches—one to hold the stationary part of the connection and one to turn the fitting. This gives you controlled leverage without putting all that torque on the hose or other components. A slow, steady pull is much more effective and safer than a sudden, jerking motion.

When to Retire a Connector

Your hose connector threaded fittings aren't lifetime parts. You have to know when to call it quits. If you see deep gouges in the metal, threads that are visibly worn down and thin, or any cracks, that connector is done. Don't try to get "one more job" out of it.

Continuing to use a compromised fitting is just asking for trouble. Keeping a few spare connectors on the truck is a small investment that will absolutely pay for itself the first time you need one in a pinch.

Hydrovac Threaded Connector FAQs

Working in the hydrovac industry, you quickly learn that the little details make a huge difference. Getting your hose connector threaded system right isn't just about efficiency—it's about safety and preventing costly downtime. Here are some of the questions that come up most often when we're talking to operators out in the field.

What Causes Threaded Connectors to Fail in Hydrovac Work?

When a threaded connector gives out, it's almost always for one of a few reasons, and they're all common hazards in our line of work.

The biggest culprit by far is cross-threading from dirt and debris. Think about it—we're surrounded by mud, slurry, and grit all day. It doesn't take much for some of that to get into the threads, which prevents a clean connection and ultimately strips them out.

Another huge one is over-tightening. I get it; your first instinct is to crank down hard on a fitting to make sure it doesn't leak. But all that extra force can actually crack the connector or warp the threads, which just about guarantees it's going to fail on you.

Finally, you've got simple vibration and wear. The constant abuse and harsh conditions on a hydrovac job site will break down even the toughest equipment over time. That's why inspecting your gear regularly is so important—you can catch the problem before it stops you in your tracks.

Expert Tip: Before you connect anything, take 15 seconds to clean the threads with a wire brush or a rag. Honestly, this one simple habit is the best thing you can do to prevent cross-threading and make your equipment last longer.

Can I Use The Hydrovac Attachment Tool with a Different Hose Size?

That's a common question, but the Hydrovac Attachment Tool was built specifically for a standard 2.5-inch wet-vac hose. We didn't pick that size at random; it's the industry standard for the kind of precision work this tool is designed for. The connector and clamp are machined to get a perfect, no-slip grip on a 2.5-inch hose, giving you the best possible suction and stability.

If you try to rig it up with a different hose size, you'll compromise the seal and the mechanical lock. You’d immediately lose vacuum power, and even worse, it could create a serious safety hazard if the whole thing comes loose while you're working. For performance and safety, you've got to stick with the recommended 2.5-inch hose.

How Do I Know if I Am Over-Tightening My Connectors?

Over-tightening is one of the most destructive—and common—mistakes we see. You're not trying to apply brute force; you're just looking for a snug, leak-proof seal.

The most obvious sign you're going too far is when you have to fight the wrench. If you feel like you need a cheater bar to get more leverage, you've already gone way too far and are probably damaging the fitting.

Pay attention to your sealant, too. If you're using Teflon tape and you see it shredding and squeezing out from between the threads, that's a bad sign. With liquid sealants, you'll see way too much ooze out. A good rule of thumb is to tighten it "hand-tight," then grab a wrench and give it another one to one-and-a-half turns. That's usually all it takes to seat the threads properly without risking damage.

Ready to stop guessing and build a standardized, leak-proof connection that works every time? The Hydrovac Attachment is built for the tough realities of vacuum excavation, turning your power washer and wet-vac hose into a precise, efficient digging tool.

Visit hydrovacattm.com to see how it can transform your workflow.