When you're running a hydrovac operation, that connection between your hose adapter and the PVC pipe is everything. It's the critical link in your excavation system. If that seal is weak or slapped together wrong, you're looking at pressure loss, leaks, and a whole lot of expensive downtime on the job. In the hydrovac industry, efficiency is paramount, and mastering this connection is your first step toward effective digging.

Getting the basics right is the first, and most important, step to building a setup that won't let you down.

Why That Hose-to-PVC Connection Is So Critical

In the world of hydrovac and wet-vac work, we push our gear to the absolute limit. That spot where your flexible vacuum hose hooks up to the rigid PVC is a classic failure point if you don't get it right. It’s more than just a simple joint—it's the gateway that has to handle massive suction, high-pressure water, and a constant barrage of abrasive gunk like rocks, clay, and slurry.

A shoddy connection will tank your performance. Even a tiny air leak compromises your vacuum power, forcing the whole truck to work harder and slowing down the dig. This isn't just a friendly suggestion—picking the right parts is non-negotiable for getting the job done efficiently and safely. A secure connection is the foundation of effective digging.

The Nuts and Bolts of a Rock-Solid Connection

To build a link you can trust, you need to know the adapters and fittings you’ll be working with out in the field. There are a few main styles, but two pop up most often in hydrovac applications:

- Threaded Adapters: These give you a really secure, mechanical seal when you pair them with the right PVC fitting. They're fantastic for high-pressure work, but you have to be meticulous with the sealing—think thread tape or a good sealant—to keep them from leaking.

- Camlock Adapters: You've probably seen these. They're all about speed—perfect for setups you need to break down and move around a lot. With camlocks, it all comes down to the gasket. A quality gasket is the only thing standing between you and a leaky mess.

The demand for good, reliable components is blowing up. In 2023, the global market for plastic pipe fittings hit a value of USD 37.61 billion. That number is expected to climb to nearly USD 54 billion by 2030. This just proves how essential solid water and debris management is in our industry. You can dig deeper into the numbers in this market analysis on plastic pipe science.

A Smarter Solution Built for the Job

Picking the right parts is key, but sometimes the best answer is an all-in-one system designed specifically for the task. The Hydrovac Attachment Tool is that solution, engineered to provide a foolproof connection for effective digging purposes.

Choosing Your Adapter and PVC Fittings

Making the right choice upfront saves a world of headaches later. This table breaks down your common options to help you match the gear to the job.

| Adapter Type | PVC Fitting | Best Use Case | Pressure Tolerance |

|---|---|---|---|

| Threaded (NPT) | Schedule 80 PVC Male Adapter (MIPT) | Permanent or semi-permanent high-pressure connections | High |

| Camlock (Male) | Schedule 40 or 80 PVC Female Adapter (FIPT) | Frequent connection/disconnection; lower pressure | Moderate |

| Barbed/Shank | Direct insertion into PVC pipe (with clamp) | Low-pressure transfer; quick, temporary fixes | Low |

| Flanged | PVC Flange Adapter | Industrial-scale systems; requires gaskets & bolting | Very High |

Ultimately, whether you're building a semi-permanent setup on-site or need the flexibility to move your lines around, matching the adapter style to the right PVC fitting and pressure rating is fundamental.

While you can piece together traditional fittings, they often mean juggling multiple parts and hoping you get every seal just right. A more modern approach is using an integrated system like the Hydrovac Attachment Tool. It was engineered from the ground up to solve this exact problem.

The Hydrovac Attachment Tool rolls the functions of several different fittings into one solid unit, getting rid of those common leak points right from the start. This makes sure all the power your vacuum generates goes straight to the tip, where you're actually digging. No loss, no fuss.

This idea of a secure, perfectly optimized connection is at the heart of modern digging. To get a better grasp of the principles behind it all, check out our guide on what vacuum excavation is. Starting with a bulletproof connection is your first step toward a safer, more productive operation.

Getting It Right: How to Prep for a Perfect Fit

A rock-solid connection is made long before you ever touch a clamp. I've seen it a hundred times: operators skip the prep work and end up with leaks and lost suction right in the middle of a job. Taking a few minutes to get your components ready is the real secret to a perfect, lasting seal when connecting a hose adapter to PVC.

First things first, get your measurements right. Don't just eyeball it or trust the size stamped on the part. Grab a pair of calipers and get a precise Outer Diameter (OD) on your PVC pipe and an equally precise Inner Diameter (ID) on your vacuum hose. Manufacturing tolerances can vary, and a small mismatch is all it takes to create a major headache.

Clean and Check Your Gear

Once you know your sizes are compatible, it's time to create a clean, smooth surface for everything to mate up. Any grit, grime, or burrs left on the pipe can kill your seal before you even start.

- Wipe it Down: Use a clean rag to wipe the inside of the hose end and the outside of the PVC. Get rid of any mud, oil, or debris that could get trapped.

- Deburr the Pipe: If you just cut the PVC, that edge will be rough and sharp. Use a deburring tool or even a utility knife to knock that edge down and create a slight bevel. This stops it from tearing a gasket or preventing the hose from sliding on all the way.

- Give Everything a Once-Over: Look closely at your hose adapter and any fittings. You're searching for hairline cracks or defects from the factory. A tiny flaw can turn into a massive failure under the suction of a hydrovac.

This isn't just busywork. It's a fundamental step for any setup, from a basic shop vac to a high-powered hydrovac. For a deeper dive into how different attachments work with various hoses, check out our guide on shop vac hose attachments.

Don't Skip the Dry Fit

Before you even think about grabbing sealant or clamps, always do a dry fit. Just slide all the pieces together—hose, adapter, and PVC—with no adhesives or fasteners. This is your one chance to spot a problem before it’s too late.

A quick dry fit tells you if everything lines up without being forced. If you're using the Hydrovac Attachment Tool, this is when you confirm it sits flush against both the hose and pipe. That’s the foundation you need for a powerful, leak-free connection.

Think of it as a dress rehearsal. It lets you see how it will all come together in the real world. You might find a hose is too stiff to align easily or a fitting that just won't seat right, saving you from having to tear it all apart later.

Creating a Leak-Proof Seal That Lasts

In hydrovac work, a solid, leak-proof seal is what separates the pros from the rookies. Once you’ve prepped your components, the real test begins. Getting the seal right on your hose adapter to PVC connection is what ensures your setup will survive the brutal conditions on a job site—we’re talking intense vibration, high-pressure flow, and constant abuse.

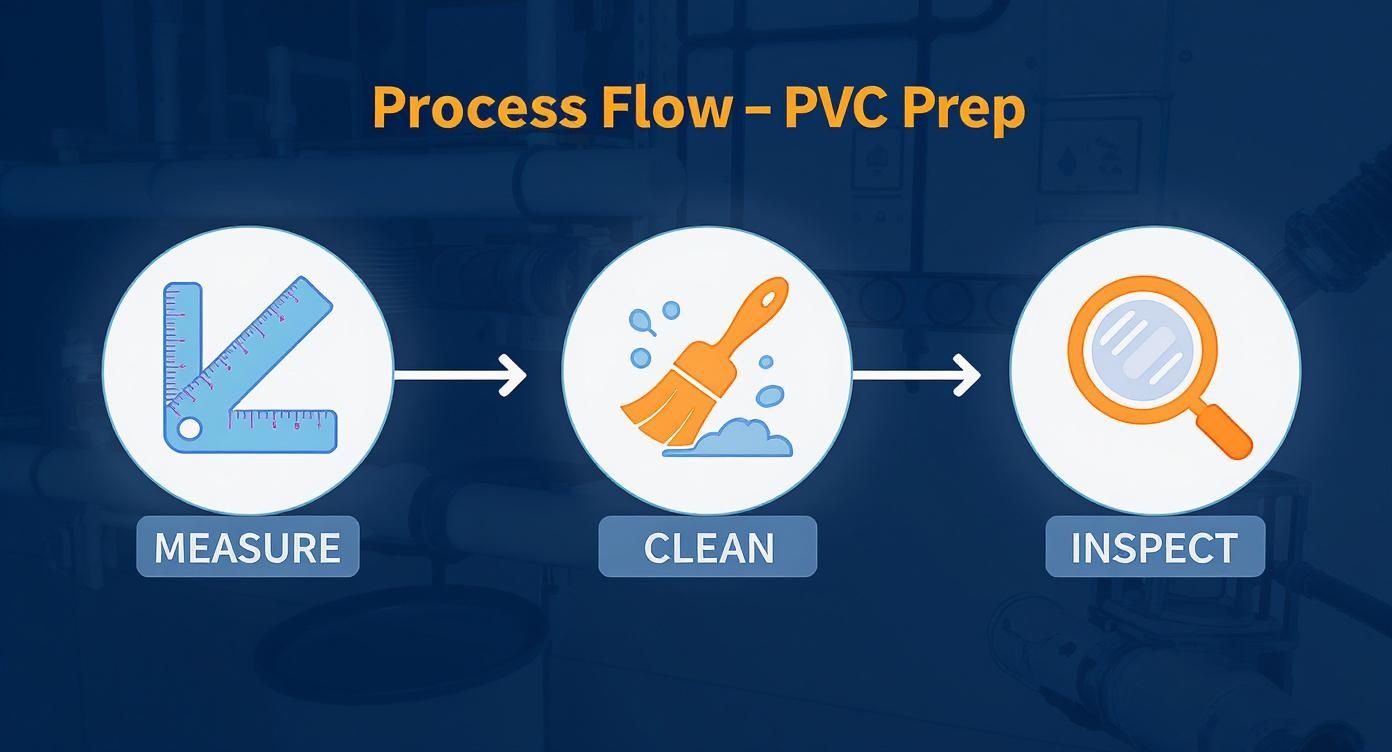

Before you even think about connecting anything, your prep work has to be flawless. This quick guide breaks down the essentials: measure, clean, and inspect.

This isn't about brute force. A reliable connection is built on a methodical process that ensures every piece is perfectly ready for assembly.

Mastering Different Sealing Methods

The kind of adapter you're working with will determine your sealing strategy. Each type needs a specific touch to create a bond that won't give up under pressure. Messing up these details is a surefire way to get frustrating leaks and a drop in performance right in the middle of a critical job.

- For Barbed Adapters: It’s all about proper clamp placement. I always position my clamps about a quarter-inch from the end of the hose. This gives you maximum grip without chewing up the hose material. Remember, you want to compress the hose firmly onto the barbs, not crush the life out of it.

- For Threaded Connections: Thread sealant is not optional. Whether you prefer PTFE tape or pipe dope, how you apply it matters. Always wrap the tape clockwise on male threads—that way, it won't bunch up or unravel when you tighten the fitting. If you're using dope, a thin, even coat on the male threads is all you need; too much will just gum up your system.

- For Camlock Systems: Your seal lives and dies by the gasket. Before you snap those arms down, give the gasket a quick look. Check for any nicks, cracks, or flat spots from over-compression. A misaligned gasket is a guaranteed leak, especially under heavy vacuum.

The demand for these reliable components is exploding. The global market for PVC and CPVC pipe fittings was valued at USD 25.04 billion in 2024 and is on track to hit nearly USD 41 billion by 2033. That growth just underscores how critical these connections are to building and maintaining modern infrastructure. You can discover more insights about this market growth on grandviewresearch.com.

Pro Tips for a Bulletproof Connection

A few extra tricks can make a huge difference out in the field. When I’m setting up high-pressure lines, I often use two opposing clamps for extra security against slippage. It’s a simple step, but it can stop a hose from blowing off during a pressure surge, which is a common and dangerous point of failure.

When you have a solid seal, you can feel the difference in performance. The vacuum is stronger, the material moves faster, and you can focus on the excavation itself instead of worrying about your equipment failing.

With the Hydrovac Attachment Tool, this whole process gets a lot easier. Its design integrates the connection into a single, beefy unit that’s engineered to hold a secure seal without a bunch of extra clamps or sealant. This purpose-built solution is designed for effective digging, saving time on setup and eliminating the common points of failure that plague operators in the field. You can learn more about how the right tools make a difference in our guide to hydrovac excavation equipment. At the end of the day, it's all about building a system you can trust, one solid connection at a time.

Testing Your Connection and Fixing Field Issues

https://www.youtube.com/embed/eKJRTpwcfkY

Okay, so you've got your hose adapter connected to the PVC. It looks solid, but don't just fire up the vac and hope for the best. That’s a classic rookie mistake that can lead to a huge mess. A few minutes of testing right now will save you a world of hurt later.

You don't need to go full throttle. Just run a low-pressure water test. Push enough water through the line to build a little pressure, then get your eyes on every inch of that connection. Walk it from the hose, over the adapter, and onto the PVC.

What are you looking for? Even the tiniest drip. A little bead of water forming around a clamp or a slow seep from a threaded joint might not seem like a big deal, but it's a huge red flag. Under the powerful suction of a hydrovac, a small water leak becomes a massive air leak, and that will absolutely kill your digging performance.

Field Fixes for Common Headaches

Out on a job site, things go wrong. Even the most carefully assembled connection can fail when it’s getting rattled around all day. Knowing how to spot and fix these problems quickly is what separates the pros from the amateurs.

Here are a few of the most common issues I've seen in the field and how to get them sorted out fast.

-

Clamps Working Loose: Notice your hose starting to pull away from a barbed adapter? That’s almost always a clamp issue, usually from the truck's vibration. The simple fix is to tighten it, but don't just reef on it with all your strength. Over-tightening will chew up the hose and can cause an even worse failure. If it happens again, try adding a second clamp right next to the first one, but face the screw in the opposite direction for a better grip.

-

Seals Breaking Down: If you're working with contaminated soil or chemicals, be prepared for your seals to take a beating. The rubber gaskets in camlock fittings can swell, crack, or get brittle when exposed to certain materials. If a connection that was perfect yesterday is leaking today, pop it open and inspect the gasket. I always keep a bag of spare gaskets in the truck for this exact reason.

-

Bad Hose Angles: This one is a silent killer. When your hose yanks on the PVC pipe at a sharp angle, it puts constant, uneven stress on the fitting. Over time, this can warp the adapter and create a leak that’s tough to track down. Always try to route your hose so it comes into the connection as straight as possible. A little bit of planning here goes a long way.

A lot of these headaches are just symptoms of a bigger problem: a connection pieced together from mismatched parts. That's where an engineered solution like the Hydrovac Attachment Tool really proves its worth.

By combining everything into a single, solid unit, the Hydrovac Attachment Tool gets rid of all those weak points you find in cobbled-together setups. It forces a perfect alignment and creates a bulletproof mechanical seal, so you can run your gear at full power without constantly worrying about your connection blowing apart. It's the best defense against the most common field failures and a key to more effective digging.

Troubleshooting Common Connection Failures

When you're out in the field, you don't have time for a lengthy diagnosis. Leaks and performance drops cost money and time. Here’s a quick guide to help you identify what's wrong and get back to work.

| Symptom | Likely Cause | How to Fix It |

|---|---|---|

| Whistling or hissing sound near the connection | Air leak | Tighten all clamps. Inspect gaskets in camlock fittings for cracks or damage. Check for hairline cracks in the PVC itself. |

| Visible drip or steady stream of water | Failed seal or loose clamp | Re-seat the gasket. Tighten the clamp (don't overtighten). For threaded connections, re-apply thread sealant and re-tighten. |

| Hose is pulling away from the adapter | Clamp slippage or improper hose routing | Re-position and tighten the clamp. Consider adding a second clamp. Secure the hose to reduce strain on the connection point. |

| Reduced suction power at the nozzle | Major air leak at the PVC connection | Perform a low-pressure water test immediately to pinpoint the leak. The bigger the performance drop, the bigger the leak. |

| Connection feels loose or wobbly | Stripped threads or warped fitting | Disassemble immediately. Inspect threads on both the male and female ends. If damaged, the fitting must be replaced. |

Think of this table as your first line of defense. Most problems are simple fixes, but ignoring them can lead to bigger, more expensive failures down the road.

Boosting Hydrovac Performance and Efficiency

Getting a secure connection is one thing, but an optimized one? That's what separates a good day from a great one on the job. Fine-tuning your hose adapter to PVC setup isn’t just about stopping leaks—it's about maximizing your raw digging power and moving more material in less time. Every choice you make, from the adapter size to how you lay out the hose, hits your bottom line.

The physics here are pretty straightforward. Any disruption to the airflow inside your vacuum hose kills your suction. Think of it like a river—sharp bends, internal ridges from mismatched fittings, or a sudden jump in diameter creates turbulence. That turbulence puts the brakes on the air and debris, forcing your vac truck to work way harder than it should.

And this isn't a niche problem. The market for these parts is huge. In 2024 alone, global consumption of plastic hoses and fittings reached 9.2 million tons. The total market value is on track to hit $90.8 billion by 2035, which tells you just how vital these connections are across countless industries. You can see a full breakdown in the global plastic hose and fitting market analysis at indexbox.io.

Designing for Unrestricted Flow

To keep your machine running at its peak, your goal is to create the smoothest possible superhighway from the nozzle all the way to the truck. This concept is called laminar flow, where air and material move in smooth, parallel layers without hitting any speed bumps.

Here are a few field-tested tips to get you there:

- Match Inner Diameters: This is non-negotiable. Always pick a hose adapter where the inner diameter is a perfect match for your PVC pipe. Even a small step-down creates an instant bottleneck and chokes the flow.

- Avoid Sharp Angles: Never let your hose kink into a hard 90-degree bend right off the fitting. It's probably the single biggest killer of suction power. Always aim for long, sweeping curves to keep the momentum going.

- Eliminate Internal Obstructions: Double-check that no part of a clamp, screw, or fitting is sticking into the airflow path. Even a tiny obstruction can create a vortex that slows everything down.

The Engineered Advantage

This is where a purpose-built system like the Hydrovac Attachment Tool really proves its worth. It’s not just a random collection of parts from a hardware store; it’s engineered from the ground up as a single, cohesive unit designed to preserve that critical laminar flow.

The Hydrovac Attachment Tool creates a completely seamless transition from the hose to the PVC. Its internal geometry is specifically shaped to guide airflow smoothly, which gets rid of the turbulence you’d normally get from piecing together standard fittings. In the real world, this means more of your truck's power actually makes it to the ground for faster, more effective digging.

At the end of the day, a sloppy connection doesn't just slow you down. It burns more fuel and puts a lot of unnecessary strain on your equipment. By focusing on creating a wide-open path for air and debris, you’re not just making a better connection—you’re making your entire operation more profitable.

Common Questions About Hose and PVC Connections

Even with the best parts and a solid plan, things can get tricky out in the field. When you're trying to get a solid hose adapter to PVC connection, getting a straight answer quickly can save you a ton of headaches and costly mistakes. Let's tackle some of the most common questions we hear from operators on the job.

Can I Use PVC Cement on a Barbed Hose Adapter?

We get this question all the time, and for hydrovac work, the answer is a hard no. It’s a common misconception. PVC cement isn't actually a glue; it's a chemical solvent that literally melts and fuses two pieces of rigid PVC together. It simply won't create a reliable bond with the flexible hose material or the different plastics used in many barbed adapters.

If you try to use cement, you're creating a false sense of security. The connection might seem tight at first, but under the intense vibration and powerful suction of a hydrovac, it's just a matter of time before it fails. That kind of catastrophic failure on the job is a risk nobody should take. Stick with a proper mechanical connection, like quality hose clamps on a barbed fitting or a threaded adapter assembly.

What's the Most Common Point of Failure?

Based on everything we’ve seen out in the field, the number one culprit is clamp failure on barbed fittings. Almost every single time, it comes down to improper torque. Too loose, and the hose will inevitably slip off under pressure. Crank it down too tight, and you'll bite into the hose, creating a weak point that will eventually tear.

The second biggest issue we see is using the wrong thread sealant. Some sealants just can't hold up when they come into contact with certain chemicals or contaminants in the soil, leading to those slow, nagging leaks that kill your performance.

The bottom line? Your best defense is a routine inspection. A quick check of your clamps and fittings at the start of every shift is the best way to catch a problem before it shuts you down.

How Does the Hydrovac Attachment Tool Prevent These Issues?

This is exactly why the Hydrovac Attachment Tool was developed—to completely eliminate these common failure points. Instead of having operators cobble together different parts and hope for the best, it offers a single, rock-solid unit that guarantees a perfect mechanical seal every time.

It's designed to take all the guesswork out of the process.

- Perfect Alignment: It forces a straight connection between the hose and PVC, which cuts down on the side-load stress that causes so many leaks.

- Smoother Flow: The design minimizes turbulence right at the connection, giving you a noticeable boost in suction power right where it counts.

- Built to Last: You get a stable, purpose-built interface that’s made to handle the constant vibration and rough handling that comes with hydrovac work.

By simplifying the entire connection into one rugged part, it drastically reduces the mechanical stress that causes the most frequent leaks and breaks. This lets you stop worrying about your gear and focus on the dig.

For a connection solution built to handle the toughest job sites, trust Hydrovac Attachment. You can learn more about how our patented tool makes operations faster and safer by visiting the official Hydrovac Attachment website.