Shop vac hose attachments are the specialized nozzles, wands, and connectors that take a standard wet/dry vacuum from a simple cleanup tool to a multi-purpose powerhouse. For professionals in the hydrovac industry, these add-ons are designed for everything from fine-detail cleaning and liquid pickup to demanding professional jobs like non-destructive digging.

From Cleanup Crew to Surgical Tool

Most pros in the hydrovac industry already have a shop vac kicking around the truck or shop. It’s the go-to for cleaning up dust, debris, and the occasional water spill on a job site. But the moment you try to use it for something more technical—like carefully exposing buried utility lines—you hit a wall. Its limitations become obvious, fast.

That’s where specialized shop vac hose attachments completely change the game. They can effectively transform that basic cleanup tool into a piece of equipment capable of precise, almost surgical work. This is a critical need in the modern hydrovac industry, where efficiency and minimizing site disruption are paramount.

Trying to dig around a sensitive fiber optic line with a generic, wide-mouthed floor tool is asking for trouble. You have almost no control, it sends dust and debris everywhere, and it’s constantly clogging up with the wet, heavy slurry of soil and clay. Every time you have to stop to clear a clog, you're losing time and money—a major concern in an industry where project timelines are tight.

The Problem With Standard Nozzles

Let's be honest, the plastic attachments that come in the box with a shop vac were never meant for the brutal demands of hydro excavation. Their weaknesses show up almost immediately on a real job site:

- Zero Precision: A wide nozzle creates a massive suction field, making it impossible to dig with any kind of accuracy in a tight spot or around a specific pipe. This is unacceptable in hydrovac operations where precision is key to safety.

- Non-Stop Clogging: Standard tools are built for dry sawdust, not the thick, abrasive mud you create when hydro-excavating. This means you’ll be stopping constantly to clear out the hose.

- Built to Fail: That thin plastic just can't stand up to the abuse. It will crack, wear out, and break down when blasted with sand, rocks, and high-pressure water.

This gap in performance points to a major need in the industry. As hydrovac crews hunt for more agile and efficient gear, the market for specialized tools is booming. It's not just a gut feeling; the global market for vacuum cleaner attachments was valued at around USD 3 billion in 2023 and is expected to climb to nearly USD 5.2 billion by 2032. This trend really drives home how critical the right tool is for the job, especially for hydrovac contractors.

To give you a clearer picture, here’s how standard tools stack up against purpose-built digging attachments for the hydrovac industry.

Standard Attachments vs Specialized Digging Tools

| Attachment Type | Primary Design Use | Precision Digging Suitability | Common Failure Point |

|---|---|---|---|

| Wide Floor Nozzle | General floor cleanup (dry or wet) | Very Poor | Prone to clogging with heavy, wet soil. |

| Crevice Tool | Cleaning tight corners and crevices | Poor | Too narrow for effective soil removal; clogs easily. |

| Dusting Brush | Gentle dusting of delicate surfaces | Not Applicable | Bristles get destroyed by abrasive material instantly. |

| Hydrovac Attachment | Precision hydro excavation | Excellent | Designed specifically for this task; no inherent weakness. |

As you can see, using the wrong tool for the job isn't just inefficient—it's often a recipe for frustration and broken equipment.

A Purpose-Built Solution for Precision Work

This is exactly why purpose-built solutions are so important. The Hydrovac Attachment Tool was engineered from the ground up to turn your existing shop vac into a powerful, precise digging machine.

It’s more than just another nozzle. It’s a complete system designed to marry a power washer with vacuum suction, giving you pinpoint control over the digging process. This simple but effective tool turns your workshop staple into a serious field asset, perfect for those smaller-scale jobs where bringing in a full-sized hydrovac truck just doesn't make sense.

By focusing the water jet and the suction into a single, controlled point, it delivers the accuracy you need to perform safe and effective non-destructive digging. If you're new to this method, taking a moment to understand what vacuum excavation is can give you a lot of helpful context.

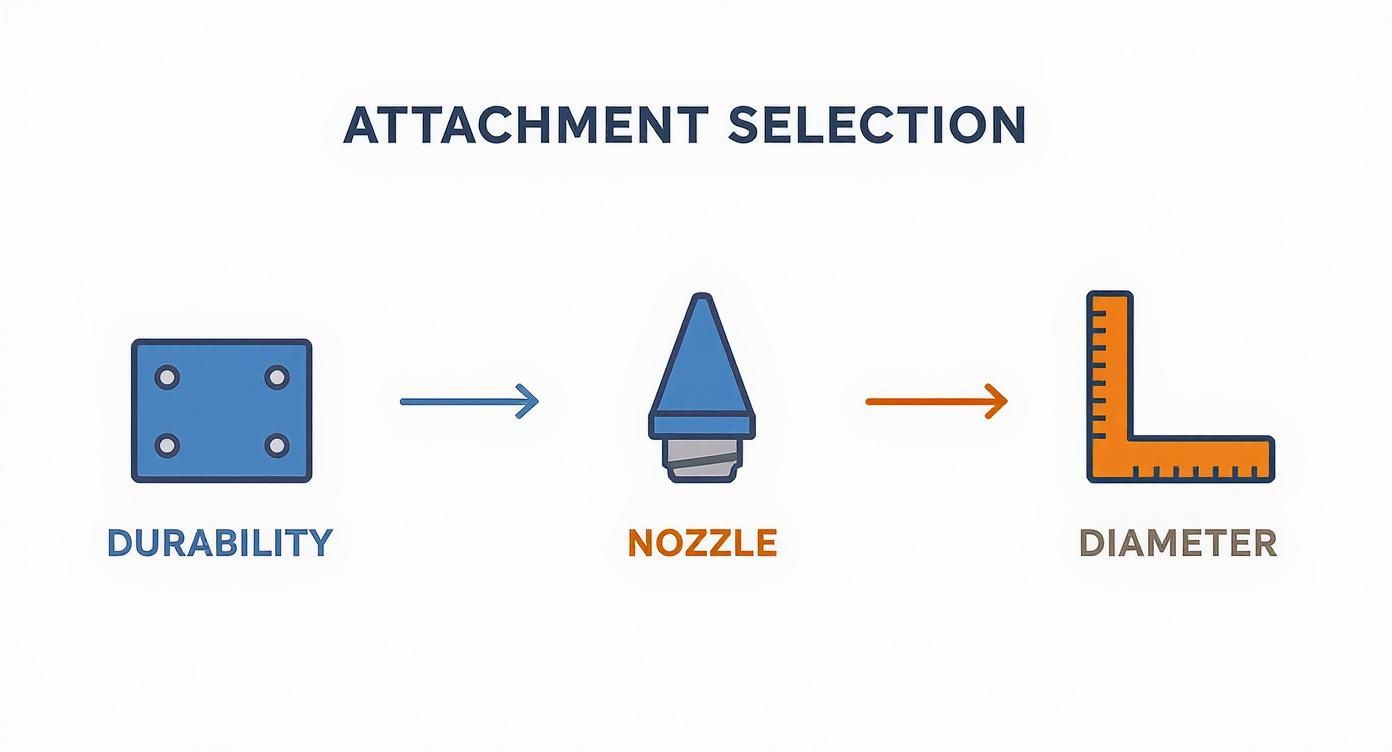

Choosing the Right Hydrovac Attachment

When you’re staring down a job that involves digging around sensitive underground lines, that flimsy plastic nozzle your shop vac came with is more than just useless—it's a risk. Not all shop vac hose attachments are built the same, and for serious hydrovac work, the right tool at the end of your hose can mean the difference between a clean, successful job and a costly disaster.

The truth is, hydro excavation is brutal on equipment. You're sucking up a high-speed slurry of water, dirt, clay, and rocks. That mixture will tear apart standard plastic attachments in no time. If you're doing this for a living, a purpose-built tool isn't a luxury; it's a necessity.

Material Durability is Everything

The absolute first thing you have to look at is what the attachment is made of. A plastic crevice tool is great for getting crumbs out of a car seat, but it has no business on a professional excavation site.

- Abrasive Wear: Think of it this way: the constant flow of sand and grit is like a sandblaster. It will eat through soft plastic, weakening the tool until it fails.

- Impact Resistance: Job sites are rough places. Drop a plastic attachment, and it can easily crack or shatter. A tool made of steel or a tough industrial polymer can take a beating and keep working.

- Pressure Tolerance: Between the high-pressure water and the intense vacuum suction, a plastic tool can start to flex and warp. Eventually, it's going to give out.

A solid, professionally designed tool like The Hydrovac Attachment Tool is built from materials that are meant for this exact environment. Its heavy-duty construction means you can trust it not to fail when you're working inches away from a gas line or fiber optic cable. It's about reliability and a tool that will actually last.

Getting Suction and Hose Size Right

It’s not just about toughness; the design of your attachment and hose directly impacts how well it works. Most pro-level shop vacs come with a 2.5-inch diameter hose for a reason—it hits the sweet spot between airflow (CFM) and pure lifting power (water lift).

If you slap on an attachment that narrows that opening, you create a bottleneck. Your suction power plummets, and you’ll spend half your day dealing with clogs. The best attachments, like The Hydrovac Attachment Tool, are designed to keep that internal pathway wide and smooth, letting debris flow freely without jamming up the works.

An attachment's internal design is just as important as its external durability. A smooth, wide bore prevents the slurry from jamming, allowing the vacuum to work at peak efficiency and keep the job moving forward.

Precision Matters for Controlled Digging

The last part of the equation is the nozzle itself. Good hydro excavation is all about using a controlled water jet to liquefy the soil without damaging what's underneath. A generic attachment gives you no way to do this, forcing you into clumsy and often unsafe workarounds trying to manage a pressure washer wand and a vacuum hose at the same time.

The Hydrovac Attachment Tool was engineered to solve this exact problem. It builds the water jet right into the vacuum head, so you have one tool that does both jobs. This integrated design contains the spray, keeps your line of sight clear, and gives you pinpoint control over where you're digging. To see how all the pieces of a professional setup come together, check out our complete guide on hydrovac excavation equipment.

Imagine you need to clean out a tight valve box packed with mud. A standard nozzle is too big and sprays everywhere. A purpose-built tool, on the other hand, lets you aim the water jet precisely where you need it while sucking up the slurry at the same time. You get the job done faster, safer, and cleaner. That’s where a steel or heavy-duty polymer tool proves its worth every single time.

Achieving an Airtight Setup for Maximum Suction

Let’s be honest: even the most powerful vacuum is useless without a solid setup. When you're running a hydrovac, getting an airtight connection between your shop vac and hose attachments isn't just a "nice-to-have"—it's everything. It's the secret to getting the raw suction power you need to get the job done efficiently. A loose connection or a leaky seal will absolutely kill your performance, turning a straightforward dig into a frustrating mess.

The whole point is to create a sealed system. You want every bit of power from that motor pulling directly from the nozzle. The second air starts leaking in from a bad adapter or a cracked hose, your vacuum’s ability to lift heavy, wet soil drops off a cliff. That means digging slower, fighting clogs, and wasting time you don't have.

Navigating Hose Diameters and Adapters

One of the biggest headaches out in the field is dealing with mismatched hoses. Shop vacs don't have a universal hose size, which often leads to a frustrating hunt for the right adapter when you’re trying to connect your vacuum to your digging tools.

You'll run into a few common diameters:

- 1.25 inches: Usually found on smaller, portable shop vacs.

- 1.5 inches: A standard size for many mid-range, household-type units.

- 2.5 inches: This is the workhorse. It’s the standard for professional-grade, high-power wet/dry vacuums.

For any serious hydro-excavation, a 2.5-inch hose is non-negotiable. The wider diameter gives you maximum airflow and is far less likely to clog up when you're sucking up that thick slurry of mud and water. A specialized tool like The Hydrovac Attachment Tool is designed from the ground up to connect seamlessly with this professional-grade hose size, so you get a secure, high-performance fit right away.

Choosing the right professional attachment is about more than just the hose, though. You have to consider everything from the material's durability to the specific nozzle design.

As you can see, a pro setup is a complete system. The strength of the materials, the function of the nozzle, and the correct hose diameter all have to work together to give you the performance you need.

Matching Your Vac to the Task

Those power ratings on the side of your shop vac? They're not just for marketing. You have to match your vacuum’s horsepower, suction (measured in inches of water), and airflow (CFM) to the demands of your attachment. Mismatch them, and you’re in for a long day. It’s no surprise these performance specs are a big deal in the global vacuum cleaner market, which brought in US$47 billion in revenue. You can get a better sense of how vacuum cleaner specs are measured on Wikipedia.

If you try to run a professional digging tool with an underpowered vacuum, you'll get weak suction and clogs—guaranteed. On the flip side, a massively overpowered unit could put too much stress on a lighter-duty attachment. Finding that sweet spot means your gear works better and lasts longer. If you want to dig deeper into how engine types can impact performance, check out our post on gasoline-powered vacuum systems.

Pro Tip: Before you start a big job, do a quick leak test. Fire up the vacuum and run your hand along the hose and every connection point. If you feel any air being sucked in, you’ve found a leak that's stealing your power. Seal it up.

Finally, make sure your attachment is locked on tight. A tool like The Hydrovac Attachment Tool, which is blasting high-pressure water and sucking hard at the same time, generates a lot of force. If that connection is loose, the attachment could fly off, creating a serious safety hazard and bringing the job to a screeching halt. Always double-check that your connection is fully seated. For extra peace of mind, a hose clamp is a great idea. It’s a simple step that makes your setup powerful, safe, and reliable.

Field Techniques for Non-Destructive Digging

Theory is one thing, but getting your hands dirty is where the real learning happens. Once you’re geared up, your shop vac and its specialized hose attachments become a serious tool for non-destructive digging. This isn't just about sucking up dirt; it's about mastering techniques that let you work with precision and speed, especially when there are sensitive underground utilities on the line.

The secret sauce here is a purpose-built tool. The Hydrovac Attachment Tool is a game-changer because it combines a high-pressure water jet with vacuum suction into a single, handheld unit. It liquefies the soil and whisks it away in one smooth motion. This is what lets you perform surgical digging without calling in a massive hydrovac truck for every small-scale job.

Mastering the Art of Potholing

Potholing—sometimes called daylighting—is just a term for carefully exposing underground utilities to see exactly where they are, how deep they run, and what you're dealing with. It’s mission-critical work where a single mistake can damage a line, cause an outage, and lead to some very expensive repairs.

To do it right, you have to be methodical. Start by using the integrated water jet on The Hydrovac Attachment Tool to gently soften the ground directly over the marked utility. Don't get too close—keep the nozzle at least 4-6 inches away and use a sweeping motion. This turns the soil into a slurry without blasting the utility itself with high-pressure water.

As you break up the soil, the vacuum sucks the material away instantly, so your line of sight stays clear. This is a huge advantage over digging blind with a shovel. You see exactly what you’re doing every step of the way, which brings the risk of an accident way down.

Trenching Along Sensitive Infrastructure

What if you need to dig a narrow trench right alongside an existing pipe or cable? This is where a focused tool really proves its worth. Instead of digging a wide, disruptive trench with heavy equipment, you can create a clean, narrow channel with minimal impact.

The angle of attack is everything when trenching. Avoid pointing the nozzle straight down. Instead, hold The Hydrovac Attachment Tool at roughly a 45-degree angle, aiming the water jet slightly away from the utility. This lets the water undercut and loosen the soil, allowing the vacuum to pull it away cleanly.

It's a subtle but critical adjustment. This technique prevents you from spraying high-pressure water directly onto the utility, which could easily damage protective coatings or the line itself.

By combining a controlled water jet with powerful suction in one tool, you can trench with surgical precision. This approach minimizes the excavation footprint, reduces backfill requirements, and protects the surrounding infrastructure from damage.

Handling Different Soil Conditions

Not all dirt is created equal, and your technique has to adapt to what you find underground. Different soil types demand different approaches, and a versatile shop vac hose attachment gives you the control to adjust on the fly.

- Loose, Sandy Soil: This is the easy stuff. You can often dial back the water pressure and just focus on keeping a steady flow of material moving through the hose to avoid clogs.

- Thick, Compacted Clay: Now we're talking. Clay requires more water pressure and a bit more finesse. Use short, controlled bursts from the water jet to fracture it into smaller, manageable chunks that the vacuum can actually handle. Don’t try to chew off more than you can handle at once; work in layers.

- Rocky or Gravelly Soil: Here, the goal is to use the water to wash away the finer material surrounding the rocks. Once the dirt and sand are gone, the vacuum can usually pick up the smaller stones. Anything bigger might need to be removed by hand after you've exposed it.

Cleaning Out Cramped and Awkward Spaces

One of the biggest wins for this kind of setup is its ability to get into places a hydrovac truck could only dream of. Think about cleaning out a sump pump basin, a cramped utility vault, or a storm drain packed solid with mud and leaves.

In these tight quarters, maneuverability is everything. The Hydrovac Attachment Tool's focused design lets you point the suction and water exactly where it needs to go without creating a huge mess. You can clean out tight corners, work around existing pipes, and remove years of sludge in minutes. It turns a miserable, manual job into a fast, clean, and much safer operation, making it one of the most effective shop vac hose attachments for tough industrial tasks.

Keeping Your Digging Tools in the Fight

Professional gear needs professional care, and your hydrovac setup is no exception. Getting the right shop vac hose attachments is a great start, but keeping them—and your crew—safe and effective is all about solid maintenance habits. This isn't just about making your equipment last longer; it’s about making sure it works reliably every single time you fire it up on a job site.

Let’s be real: mixing high-pressure water with a powerful vacuum creates some serious safety considerations. The basics are a must—always gear up with the right Personal Protective Equipment (PPE) like eye protection and waterproof gloves. But a hidden danger many crews overlook is static discharge. When dirt and debris fly through the hose that fast, static can build up, creating a nasty shock hazard. Always make sure your equipment is properly grounded.

Your End-of-Day Maintenance Routine

Spending a few minutes cleaning up after a job can save you from major headaches and costly downtime later on. The slurry and muck from hydro-excavation are incredibly abrasive and can wreak havoc on your tools. A consistent routine is your best defense.

The first thing to check is The Hydrovac Attachment Tool. The drilling mud and whatever else you're sucking up can be corrosive. A quick rinse with clean water after each use is all it takes to stop corrosive gunk from building up and eating away at the tool.

Here's a quick checklist to run through after you wrap up:

- Scan Hoses for Wear: Give every inch of your hoses a once-over. Look for cracks, splits, or any spots that look thin or worn. A bad hose kills your suction and is a blowout waiting to happen.

- Tighten Every Connection: Check all your fittings, from the vacuum itself to the nozzle. Loose connections are the number one reason for suction loss.

- Clear Out the Vacuum Filter: A clogged filter chokes your machine. If your vacuum isn't pulling like it used to, this is the first place to look. Clean or replace it often to keep the machine running at full strength.

Think of equipment care as a direct investment in your business. A tool that's well-maintained is a tool you can count on, and that reliability is what keeps projects moving and clients satisfied.

Catching Problems Before They Start

The real pro move is spotting wear and tear before it causes a failure. Over time, even the toughest shop vac hose attachments will start to show their age. Keep a close eye on The Hydrovac Attachment Tool, looking for any signs of abrasion, especially around the business end of the nozzle where it sees the most action.

This push for durability is a big deal across the entire industry. The global vacuum cleaner market is worth a staggering USD 14.93 billion, and for commercial users, downtime is a killer. That’s why the top brands focus on building rugged, job-specific attachments that can take a beating. You can dive deeper into the competitive vacuum cleaner market on grandviewresearch.com.

At the end of the day, your tools are a reflection of your work. Treat them right, and they’ll perform when it counts, protect your investment, and help keep everyone on site safe.

Common Questions from the Field

Out on a job site, questions are inevitable. Even with top-tier gear, situations pop up. When you're doing non-destructive digging, getting the right answers quickly can be the difference between a smooth project and a costly mistake.

We've pulled together some of the most frequent questions we hear from professionals using shop vac hose attachments for hydrovac work. These are the real-world problems crews run into, and the answers are direct from our experience.

Can Any Shop Vac Handle Hydro Excavation Work?

The short answer is no. While pretty much any shop vac can create suction, not all of them have the muscle needed for hydro excavation. You're looking for a machine with serious power—specifically, a high water lift rating for raw pulling force and enough CFM to keep the air moving. To have any hope of moving that heavy, wet slurry you create when digging, you need a unit with at least 5-6 peak horsepower.

But honestly, the vacuum itself is only half the equation. The real difference-maker is what's on the end of that hose. A standard plastic nozzle is going to clog up instantly and doesn't have the integrated water jetting you need to dig effectively. This is where a specialized tool like The Hydrovac Attachment Tool comes in; it’s built from the ground up to combine water and suction into one efficient digging system.

What’s the Biggest Mistake People Make with These Attachments?

Without a doubt, the single most common—and expensive—mistake is trying to force a generic attachment to do a professional digging job. Trying to use a standard crevice tool or a floor nozzle for hydro excavation is a recipe for frustration. You'll deal with constant clogging, work at a snail's pace, and, worst of all, run a dangerously high risk of striking and damaging underground utilities.

Those basic plastic tools are made for sawdust and dry debris, not for handling a high-pressure water jet or sucking up an abrasive slurry of mud, sand, and rock.

Investing in a purpose-built tool isn’t just a good idea; it's essential for professional-grade work. Think of it as an investment in safety, precision, and efficiency that pays for itself by preventing damage and cutting down your time on site.

This exact problem is why The Hydrovac Attachment Tool was created. It fills that gap by providing a tough, professional solution that can actually handle the conditions you face every day.

How Can I Keep My Shop Vac Hose from Clogging?

Stopping clogs is all about technique and having the right gear. If your hose is constantly jamming up, it’s a clear signal that the balance between water, air, and your equipment is off.

Here’s a three-part approach to keep material flowing:

- Use Enough Water: First things first, you need enough water to turn that compacted soil into a liquid slurry that can actually be vacuumed. If you're too stingy with the water, you just end up with a thick, heavy paste that won't go anywhere.

- Use the Right Tool: The design of your attachment is huge. You need something with a smooth, wide internal path for the material to travel through. This is a core design feature of The Hydrovac Attachment Tool, which was engineered specifically to eliminate the bottlenecks that cause clogs.

- Keep the Air Moving: Try not to bury the nozzle completely in the thickest part of the mud. If you hear the vacuum motor start to strain, that’s your cue to lift the tool up for a second. This introduces a quick burst of air into the hose, which helps break up any potential jams and keeps the slurry moving along.

Get this combination of technique and equipment right, and you’ll spend a lot less time troubleshooting and more time getting the job done.

Is a Metal Attachment Really Better Than a Plastic One for Digging?

For hydro excavation? Absolutely. It’s not even a fair fight. A durable metal or industrial-grade polymer attachment will always outperform a standard consumer-grade plastic one.

The simple truth is that job sites are brutal environments.

- Durability: Standard plastic attachments just can't take the abuse. They crack under the intense suction and wear out fast from the constant abrasion of rock and sand.

- Control: They also lack rigidity. A flimsy plastic nozzle will flex and bend right when you need precise, steady control near a sensitive utility line.

A well-built tool like The Hydrovac Attachment Tool is made from materials chosen specifically to survive these conditions. That means it's not only more reliable in the long run but also a much better return on your investment, giving you the strength and control needed to work safely.

For crews who value efficiency and precision, the right tool changes everything. The Hydrovac Attachment provides a purpose-built solution that turns your professional shop vac into a powerful, non-destructive digging machine. Upgrade your toolkit and see the difference on your next job by visiting hydrovacattm.com.