For hydrovac operators, tackling a deep excavation with a standard vacuum wand is a classic case of being penny-wise and pound-foolish. This initial compromise quickly escalates into significant hidden costs, impacting both project timelines and site safety. Anyone who has spent time on a hydrovac truck knows that inadequate equipment is the first bottleneck on any complex job.

In the field, a standard-issue wand can turn a routine dig into a strenuous, time-draining ordeal. This is the point where specialized tools, like The Hydrovac Attachment Tool, transition from a luxury to a necessity for effective and profitable digging. It's an industry-wide shift toward solutions that directly address the challenges of modern hydro excavation.

The Hidden Costs of Standard Hydrovac Wands

In the hydrovac industry, relying on default wands for complex jobs is a direct path to inefficiency. The limitations of basic equipment create real-world hurdles that operators face daily, leading to operational delays, increased physical strain on crews, and unacceptable safety risks.

Operational Inefficiencies and Delays

Imagine daylighting utilities buried 15 feet down or navigating a dense network of underground infrastructure. Attempting this with a wand that's too short is a logistical nightmare.

Operators are forced into awkward, unstable positions, struggling to achieve the right angle while maintaining control and visibility. This constant repositioning and guesswork inflates job times far beyond initial estimates. A dig that should be straightforward becomes a slow, methodical fight against equipment limitations. These delays create a ripple effect, pushing back project timelines and driving up labor costs—a critical concern in the competitive hydrovac market.

Amplified Physical Strain on Crews

Standard wands were never ergonomically designed for the demands of deep or prolonged hydro excavation. The continuous effort required to manage a clunky, unwieldy tool at a distance puts significant strain on an operator’s back, shoulders, and arms.

This physical toll is more than just discomfort; it is a direct cause of crew fatigue, which in turn leads to a higher rate of mistakes and a drop in productivity. Over time, this repetitive strain can result in costly musculoskeletal injuries, impacting both the operator's well-being and the company's bottom line.

The real cost of inadequate equipment isn't on the invoice. It's measured in lost hours, crew burnout, and the heightened risk of a utility strike that a purpose-built tool like The Hydrovac Attachment Tool could have easily prevented.

This push for better, more efficient equipment is being felt across the industry. In fact, the commercial segment for vacuum attachments, including vacuum wand extensions, is projected to grow at a CAGR of 12.3% from 2026 to 2033. This growth is being driven by the demand for tools that save time and boost performance. You can read more about this market trend on Grand View Research.

Increased Safety and Financial Risks

Ultimately, the most critical cost is safety. When an operator lacks clear visibility or precise control over the wand's tip, the risk of a utility strike skyrockets.

A damaged gas line, water main, or fiber optic cable can lead to catastrophic project setbacks, enormous repair bills, and severe safety hazards for everyone on site. The precision offered by a dedicated solution like The Hydrovac Attachment Tool is more than a feature—it’s a strategic investment in risk mitigation. By providing operators with superior reach and control, it significantly reduces these risks, ensuring projects are completed safely, on schedule, and within budget.

How to Choose the Right Vacuum Wand Extension

Selecting the right vacuum wand extension is about more than adding reach; it's a strategic decision that directly impacts crew efficiency, job site safety, and your bottom line. In the hydrovac industry, the right tool for the job can mean the difference between finishing ahead of schedule and struggling with equipment that isn't up to the task. It requires looking beyond basic specs to what truly matters in the field.

Material composition is a key starting point. A lightweight aluminum extension may seem ideal for reducing operator fatigue, but it may not withstand the abrasive conditions of aggressive trenching. Conversely, a heavy-duty steel wand offers durability but adds significant weight, leading to faster operator burnout.

The goal is to find the optimal balance between durability and usability. This is where engineered solutions like The Hydrovac Attachment Tool excel. It is constructed from an industrial-grade polymer, delivering the ruggedness required for demanding hydrovac work without the back-breaking weight of steel, making it a versatile and effective choice for a wide range of digging applications.

Matching the Tool to the Task

The specific hydrovac application should always dictate your tool selection. The precision and control required for carefully potholing in construction to locate a single utility line are vastly different from the demands of clearing a large trench for a new foundation.

Consider these factors:

- Diameter and Suction: A wider wand is ideal for moving large volumes of loose material quickly. However, for cutting through compacted soil or clay, a narrower diameter increases suction velocity, concentrating cutting power precisely where it's needed.

- Connection Security: This is non-negotiable. A loose or sloppy connection compromises suction power and presents a major safety hazard. An extension detaching under full pressure is a dangerous event. A secure, easy-to-use locking mechanism is essential.

- Versatility: If your crew switches between potholing, trenching, and daylighting, a single-purpose tool is inefficient. A modular system that adapts to various job requirements is a much smarter long-term investment.

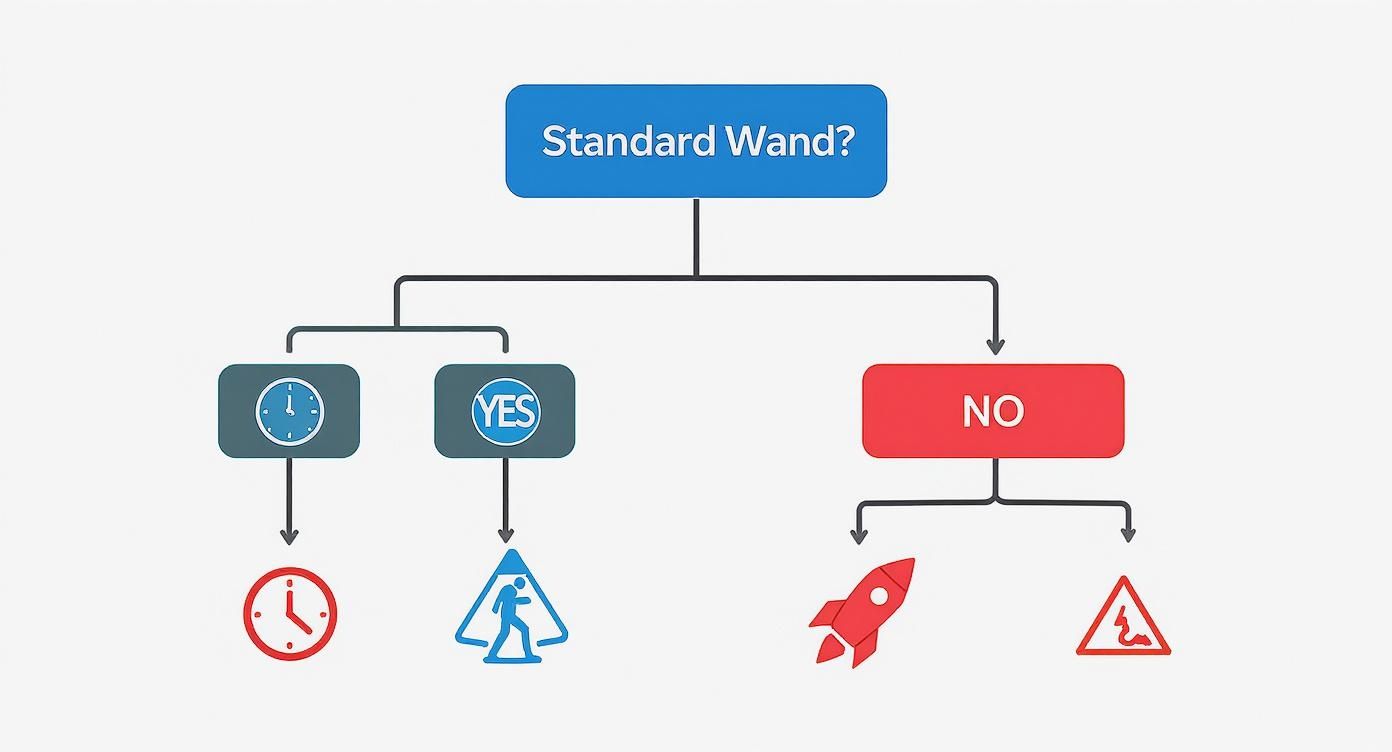

These considerations highlight why sticking with a standard wand is often a recipe for operational headaches, leading to delays, increased risks, and a fatigued crew. This flowchart illustrates the decision-making process.

As the chart shows, the standard wand may seem like an easy choice, but it often leads to operational strain and safety risks. Upgrading to a purpose-built extension is a direct path to enhanced productivity and safety.

Focusing on Performance and Compatibility

Ultimately, the best vacuum wand extension is one that integrates seamlessly into your current operations. Compatibility extends beyond just connecting to your hose; it’s about enhancing your entire workflow. You can get a deeper dive into selecting compatible hydrovac excavation equipment in our detailed guide.

When evaluating a new wand extension, compare its features against the demands of your most common jobs. This table breaks down what to prioritize for different hydrovac tasks.

Hydrovac Wand Extension Feature Comparison

| Feature | Importance for Potholing | Importance for Trenching | Importance for Daylighting |

|---|---|---|---|

| Lightweight Material | High - Operator needs to make precise, repetitive movements, so minimizing fatigue is key. | Medium - Important for long trenches, but durability can be a higher priority. | High - Requires sustained control around sensitive infrastructure. |

| Narrow Diameter | High - Increases suction velocity for surgical precision and cutting through compacted soil. | Low - A wider diameter is often better for moving larger volumes of spoil. | Medium - Good for focused digging, but a wider option might be needed for clearing areas. |

| Secure Locking System | Critical - Essential for safety and maintaining consistent suction in a confined space. | Critical - Prevents dangerous detachment under the high stress of bulk excavation. | Critical - Non-negotiable for operator safety when working near live utilities. |

| Durability | Medium - Less abrasive work, but still needs to withstand job site conditions. | High - Must resist constant abrasion from rock, debris, and soil movement. | Medium - Needs to be tough, but the work is generally less aggressive than trenching. |

By weighing these features against your typical jobs, you can identify an extension that truly meets your operational needs.

View your wand extension as a core component of your hydrovac system, not merely an accessory. The right tool enhances the performance of the truck and the entire crew, delivering measurable gains in speed and safety.

By focusing on the right material, job-specific features, and a secure connection, you can equip your crew with a tool that truly empowers them. The Hydrovac Attachment Tool was engineered with these factors in mind, providing operators the control, reach, and reliability needed to tackle any hydro excavation challenge effectively.

Mastering Digging Techniques with Extended Wands

Equipping your hydrovac truck with a high-quality vacuum wand extension is the first step; mastering its use is what distinguishes elite operators. Proper technique directly impacts digging speed, site cleanliness, and, most critically, safety. Simply attaching an extension without adapting your approach means leaving significant efficiency gains on the table.

The key is to transition from viewing the extension as a simple tube to treating it as a precision instrument. With a tool like The Hydrovac Attachment Tool, operators can shift from a brute-force approach to a more strategic, controlled methodology, turning a challenging dig into a smooth and efficient operation.

Optimizing Your Digging Stance and Angle

Operator technique is where performance is truly unlocked. The angle of attack on the soil can determine the success of a dig, especially in challenging conditions like hardpan or dense clay.

A shallow angle, nearly parallel to the ground, is highly effective for breaking up the initial surface layer. Once the surface is fractured, a steeper angle allows for deep penetration and efficient material removal.

Equally critical is maintaining the optimal distance between the nozzle and the soil. Too far, and you lose water pressure and suction, resulting in a slow, messy process. Too close, and splashback can obscure visibility. The ideal distance is typically a few inches, maximizing cutting power while ensuring immediate spoil removal.

The objective is a clean, continuous excavation process. A skilled operator with an extended wand creates a fluid motion, simultaneously cutting with water and clearing with suction, which dramatically accelerates the job.

Job-Specific Strategies for Maximum Impact

Every hydro excavation project is unique, requiring a flexible technique. The aggressive approach used to clear soil around a robust concrete water main would be inappropriate for exposing fragile fiber optic lines.

- For Delicate Utilities: Finesse is key. Use a wider spray pattern and maintain a greater distance to gently wash away soil. Work in systematic, horizontal layers to carefully peel back the earth without causing damage.

- For Compacted Soil: This requires a more powerful approach. A focused, zero-degree nozzle is the ideal tool. Use short, powerful bursts at a steep angle to fracture the soil, then pull back slightly to vacuum the loosened material.

- For Large Trenches: A grid-like pattern is the most efficient method. Work in small, manageable sections, clearing one area completely before moving to the next. This prevents rework and ensures a clean, uniform trench.

Mastering these techniques gets to the heart of what The Hydrovac Attachment Tool is designed for: precise, safe, and efficient digging. The demand for this level of performance is growing rapidly across the industry.

In 2023, the global market for vacuum cleaner attachments, which includes these wands, hit about USD 3 billion. It's projected to climb to USD 5.2 billion by 2032. You can explore the market projections for vacuum attachments on Volza.com. By refining your technique, you are not just working smarter—you are staying ahead in a competitive market. A quality tool paired with expert handling is what elevates a good crew to a great one.

Putting Safety First on the Job Site

When you integrate a vacuum wand extension into your hydrovac operation, you fundamentally alter the dynamics of the job site. It's not just about deeper reach; it introduces new physics and potential risks that the entire crew must understand and respect. This is about ensuring safety while working around critical and often fragile underground infrastructure.

A proactive safety mindset must be in place long before the hydrovac truck is started. A pre-operation checklist is not busywork; it's a critical step that can prevent catastrophic failure.

Pre-Operation Safety Checklist

Before any digging begins, a thorough equipment inspection is mandatory. Rushing this step can lead to component failure under pressure—a dangerous and costly event.

Your pre-dig check should always include:

- Check Your Connections: Physically confirm that every connection point between wand sections is securely locked. A loose connection compromises suction and can turn a section of pipe into a high-speed projectile.

- Look for Damage: Conduct a detailed visual inspection of the entire extension. Look for cracks, stress fractures, or unusual wear, paying close attention to seals and locking mechanisms.

- Clear the Zone: Walk the work area to identify and mark all potential hazards, including overhead power lines, low-hanging branches, and known underground utilities. A longer tool creates a larger swing radius that must be clear of obstructions.

This checklist is your first line of defense. Even with robustly built tools like The Hydrovac Attachment Tool, which features a solid locking system, final responsibility rests with the operator to verify that all equipment is ready for safe operation.

Safety isn't an accident. It's the result of diligent preparation and constant awareness. A few minutes spent on a pre-op check can save hours of downtime and prevent serious injury.

Ergonomics and Situational Awareness

A longer tool creates more leverage, placing increased physical strain on the operator. Musculoskeletal injuries are a significant issue in the hydrovac industry due to the handling of heavy equipment. Crews must be trained in proper lifting techniques, maintaining a stable stance, and avoiding overreaching.

Situational awareness must also be heightened. With vacuum wand extensions, the operator must be hyper-aware of the tool's position at all times, especially when potholing in construction near live utilities.

The tip of a 15-foot wand can swing into an unmarked line or another hazard in a split second. Maintaining constant awareness is what transforms a powerful tool into an effective and safe asset, rather than a liability.

Extending the Life of Your Equipment

In the hydrovac industry, equipment is your lifeline. Well-maintained tools perform reliably, last longer, and protect your bottom line. With vacuum wand extensions, neglecting maintenance is a direct route to expensive downtime and on-the-job failures.

The key to maximizing the lifespan of your extensions is a simple and consistent care routine. Incorporating a few quick checks into your daily wrap-up allows you to identify minor issues before they become major problems, keeping your crew productive and your equipment operational.

Building a Simple Maintenance Routine

An effective maintenance schedule doesn't need to be complex. It’s about building solid habits that focus on the high-wear components of your wand extensions. A few minutes of prevention can save hours of future headaches.

Make these two checks non-negotiable:

- Daily Clean-Out: At the end of every shift, thoroughly flush the wand extension with clean water. This critical step prevents mud, slurry, and debris from drying and hardening inside, which is the primary cause of clogs and suction loss.

- Weekly Inspection: Once a week, conduct a more detailed inspection. Check all seals and gaskets for cracking or wear. Examine the locking mechanisms and connection points to ensure they engage securely without any play.

These routines are more than just best practices; they are a response to a global industry trend. The demand for reliable vacuum attachments is growing as more companies recognize the value of high-performance tools. In fact, between 2026 and 2028, the Asia-Pacific market for these attachments is expected to grow at a CAGR of over 10.2%, driven by the need for dependable equipment.

Troubleshooting Common Extension Issues

Even the best-maintained equipment can experience issues. Knowing how to quickly diagnose and fix common problems is a valuable skill that keeps projects on track.

If you experience a sudden loss of suction, the first step is to check for a blockage. Disconnect the extension and look through it; if you can't see daylight, you've likely found the issue. Another common culprit is a leaky connection point—listen for the tell-tale hissing sound of an air leak.

A significant drop in suction power is rarely a mystery. Nine times out of ten, it's either a clog inside the wand or a compromised seal at a connection. Checking these two areas first will solve the problem most of the time.

This is where superior design makes a tangible difference. The Hydrovac Attachment Tool, for example, is built with smooth internal surfaces and heavy-duty seals. This design not only helps prevent clogs from forming but also makes the tool easier to inspect and clean. This smart engineering means less downtime and more time focused on the job.

Common Questions About Hydrovac Wand Extensions

When considering adding new gear to your hydrovac operation, it's essential to ask the right questions. You need assurance that a tool will not only solve a problem but also integrate smoothly with your existing truck and crew workflow. Here are answers to some of the most common questions from hydrovac operators.

How Do I Know an Extension Will Fit My Hydrovac Truck?

This is the most critical initial question. Nothing is more frustrating than a new tool arriving on-site only to discover it's incompatible with your rig.

Before purchasing, confirm the diameter and connection type of your primary vacuum hose. While most trucks use standard sizes, assumptions can lead to costly delays. A quick measurement is all it takes to avoid this headache.

Reputable extensions are designed with compatibility in mind, providing clear specifications and sometimes offering adapters for a secure, airtight seal. The Hydrovac Attachment Tool, for instance, was engineered with universal connectors to fit major hydrovac models, eliminating guesswork. A perfect fit is crucial for achieving maximum suction power from the start.

Will a Longer Wand Extension Weaken My Suction?

This is a valid concern based on fluid dynamics. Adding length to any vacuum system technically increases the distance air must travel, which can lead to a minor pressure drop. However, a professionally engineered extension is designed to minimize this loss to a nearly unnoticeable level.

The key lies in the design details: a high-quality extension will feature a smooth internal bore free of ridges or obstructions that disrupt airflow. Equally important are the airtight seals at each connection point, which prevent pressure loss.

For the vast majority of hydrovac jobs, the minuscule change in airflow is a negligible trade-off for the immense advantage of deeper reach. The ability to complete the job safely and with greater precision provides a far greater productivity boost than any minor drop in raw suction power.

Ultimately, it’s about working smarter. A well-designed extension allows you to maintain the optimal angle and distance from the soil, which actually improves digging efficiency and more than compensates for any slight change in suction.

What’s Wrong with Using a Makeshift or DIY Extension?

We understand the temptation for a quick, on-site fix. However, when it comes to hydrovac extensions, a DIY solution is a poor choice for three critical reasons: safety, performance, and durability.

A homemade extension introduces a weak point into a high-pressure system. A connection failure under load puts the crew in a dangerous situation.

Professionally engineered vacuum wand extensions are fundamentally different:

- Tested Materials: They are constructed from materials specifically selected to withstand abrasive debris and high-pressure work day after day.

- Secure Locking Mechanisms: They feature locking systems tested to prevent accidental separation during operation.

- Ergonomic Design: They are balanced to reduce operator strain, a crucial factor over a long workday.

A purpose-built solution like The Hydrovac Attachment Tool is not just a purchase; it's an investment in your team's safety, your operational efficiency, and your company's reputation. It will outlast any temporary fix and deliver a far better return in the long run.

Ready to boost your digging efficiency and safety? Hydrovac Attachment provides the reach, control, and durability your crew needs to tackle any job. Upgrade your equipment today by visiting https://hydrovacattm.com.