In the demanding world of hydrovac excavation, a specialized vacuum hose attachment isn't just an accessory—it's a critical tool for boosting efficiency. By integrating a high-pressure wand with a vacuum hose, it transforms two tools into a single, precise digging instrument. For hydrovac operators, this means less mess, improved safety, and faster job completion. The Hydrovac Attachment Tool is designed as the solution for these effective digging purposes, channeling pressurized water and excavated soil directly into the suction stream.

The Next Leap in Modern Vacuum Excavation

Anyone familiar with hydrovac operations knows the daily grind. While hydro-excavation is the undisputed champion for safely digging around sensitive utilities, the process often creates significant operational challenges. Operators constantly battle messy splashback that coats equipment, adjacent structures, and client properties in mud.

This slurry not inly creates a hazardous work environment but also severely impairs visibility, making it difficult to locate underground lines accurately. This slows down the digging process and increases the risk of a costly utility strike. Consequently, extensive cleanup is required, cutting into profit margins and extending project timelines. These are not minor inconveniences; they are significant operational hurdles in the hydrovac industry.

Solving Daily Operational Challenges

This is precisely where a purpose-built vacuum hose attachment like The Hydrovac Attachment Tool becomes a game-changer. Engineered to solve these core industry problems, it fully integrates the water jet and suction hose into a cohesive unit.

By creating a contained excavation zone at the tip of the tool, it delivers immediate, tangible benefits on any hydrovac job site:

- Minimized Debris: It virtually eliminates the chaotic, muddy splashback common in traditional hydrovac digging.

- Enhanced Visibility: Operators gain a clear view of the utilities they are exposing, improving accuracy and safety.

- Increased Productivity: With cleanup time drastically reduced, crews can move to the next job faster, boosting overall efficiency.

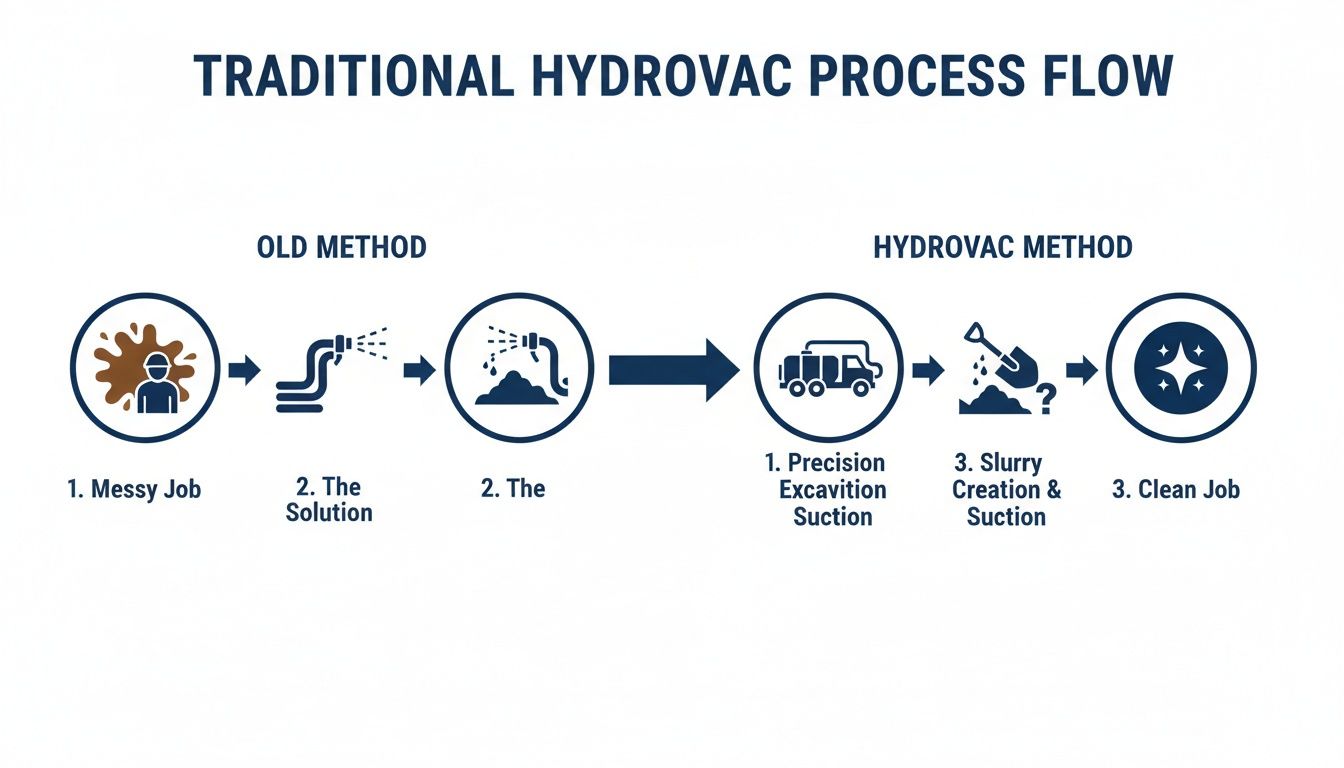

This simple diagram highlights the difference between conventional methods and the streamlined approach offered by the attachment.

The attachment is the key that transforms a messy, inefficient process into a controlled, professional hydrovac operation.

These improvements translate into significant gains in efficiency and safety. Let's examine how this solution addresses common real-world scenarios.

Traditional Hydrovac Issues vs Attachment-Driven Solutions

| Common Challenge | Impact On The Job | The Attachment-Based Solution |

|---|---|---|

| Uncontrolled Splashback | Coats equipment, buildings, and landscaping in mud. Creates a massive cleanup job. | The contained system directs all water and debris straight into the vacuum hose, keeping the site clean. |

| Poor Visibility in the Hole | Slurry and mud obscure the view of utilities, increasing the risk of an accidental strike. | With no standing slurry, operators have a clear, continuous view of pipes, cables, and conduits. |

| Slow, Inefficient Cleanup | Operators spend significant time hosing down the entire work area after the dig is complete. | Cleanup is reduced to minutes, not hours, as the mess is contained from the start. |

| Operator Fatigue & Discomfort | Constantly getting sprayed with mud and water is physically and mentally draining for the crew. | The operator stays cleaner and drier, leading to better focus, higher morale, and improved safety. |

This comparison clarifies that The Hydrovac Attachment Tool isn't just an accessory—it's a direct solution to the most persistent problems hydrovac operators face.

A Growing Industry Demands Better Tools

The global hydrovac trucks market was valued at $513.53 million in 2021 and is on track to hit an incredible $880.94 million by 2033. This growth signifies a clear industry trend: the demand for safer, more efficient excavation methods is accelerating.

This expansion highlights a critical need for smarter tools that address real-world operational pain points. To understand the fundamentals of this technique, you can learn more about what vacuum excavation is and why it has become an industry standard for non-destructive digging.

Integrating the Attachment With Your Existing Gear

Adopting a more effective digging process shouldn't require a complete overhaul of your trusted equipment. The most valuable tools are those that integrate seamlessly with your existing setup. The Hydrovac Attachment Tool was designed for precisely this purpose—a simple hook-up, not a frustrating re-configuration.

The attachment connects directly to the 2.5-inch wet vac hose, an industry standard for professional wet/dry vacs and hydrovac trucks. This compatibility allows crews to get up and running in minutes on the job site. Simply slide it on and secure it with a heavy-duty hose clamp for a solid, leak-free seal that concentrates suction power where it matters most.

Achieving the Perfect Seal and Pressure

Operators often ask about maintaining performance and preventing suction loss. The key is achieving a perfect, airtight connection. Before tightening the clamp, ensure the hose is fully seated into the attachment's base. This small step prevents air leaks that can compromise vacuum efficiency.

Once the vacuum side is secure, you can adjust your power washer's pressure to suit the soil conditions:

- Soft Loam or Sand: Lower PSI is typically sufficient to clear the soil quickly without creating excess spray.

- Compacted Clay or Gravel: Higher PSI is needed to break through tougher ground, and the attachment is built to handle it.

We specifically chose an industrial-grade polymer for the Hydrovac Attachment because it is designed to withstand the rigors of hydrovac job sites. It can endure drops, impacts, and constant exposure to the elements, making it a reliable addition to your power washer and vacuum system.

Compatibility Across Your Fleet

Whether your operation uses large hydrovac trucks or smaller, trailer-mounted vacuum units, this tool is designed for universal application. Its lightweight yet durable construction makes it easy to handle. This adaptability means any crew member can connect it and get to work, enhancing the versatility of every unit in your fleet.

A truly effective tool doesn't force you to change your workflow; it improves it. By integrating with the equipment you already own, this attachment provides an immediate boost in safety and productivity without a steep learning curve or costly new investments.

Understanding general industrial hose specifications can be a significant advantage when adding any new component. Familiarity with materials and pressure ratings ensures every part of your system works together optimally, which is especially important when moving tools between different machines.

For a broader perspective on how this attachment fits into a complete hydrovac system, explore the different types of hydrovac excavation equipment available. The more you understand each component, the more value you'll get from The Hydrovac Attachment Tool from day one.

Making Your Job Site Safer and Faster

On any hydrovac job, efficiency is profit and safety is paramount. The right vacuum hose attachment is more than a convenience; it is a strategic tool that directly enhances how safely and quickly your crew can complete their digging tasks.

The most immediate benefit is the near-elimination of hazardous splashback. In traditional hydrovac operations, flying mud and debris are a constant nuisance and a safety risk. This slurry creates dangerous slip-and-fall conditions and can damage adjacent property, leading to client dissatisfaction and potential repair costs. The Hydrovac Attachment Tool provides the solution by containing this mess.

See What You’re Doing with Surgical Precision

By containing slurry at the point of excavation, The Hydrovac Attachment Tool keeps the work area clean and dry. This controlled suction provides operators with a clear, continuous view of their work—a rare luxury in this industry. They can see utility lines as they are exposed, enabling precise and confident digging.

This constant line of sight is crucial for preventing costly and dangerous utility strikes. When your operator can see exactly what they're doing, they can protect vital infrastructure and ensure crew safety.

Smarter Tools for a Growing Market

The hydrovac industry's demand for this level of safety and precision is fueling significant growth. The US hydro excavation truck market was valued at $501.4 million in 2024 and is projected to reach $986.3 million by 2034. This trend is not surprising, given that North America accounts for over 58% of the global hydrovac truck market.

Consider this industry insight: traditional digging methods damage underground utilities in 25-30% of cases. The precision of hydro excavation, enhanced by a tool like The Hydrovac Attachment, helps prevent billions in potential repair costs. The value proposition is undeniable.

Cut Cleanup Time in Half and Watch Profits Grow

One of the largest time expenditures on any hydrovac job is cleanup. Hosing down the site, truck, and surrounding property can consume hours of valuable time.

By capturing slurry at the source, the Hydrovac Attachment turns a massive cleanup chore into a quick final touch. We're seeing crews in the field cut their total cleanup time by as much as 50%.

That saved time translates directly to your bottom line. Your crew finishes faster, allowing you to schedule more jobs and move on to the next site without a protracted cleanup. It’s the definition of working smarter, not harder, making every project more profitable.

Of course, a single tool is just one part of a comprehensive safety program. For a complete overview, review a complete guide to essential safety supplies to ensure your team is fully protected.

Putting the Attachment to Work on the Job Site

Theory is one thing, but field performance is what truly matters in the hydrovac industry. Let's examine common, real-world scenarios where this vacuum hose attachment becomes an indispensable solution for effective digging.

These are not simple digging tasks; they are jobs where precision, safety, and cleanliness are non-negotiable, and where The Hydrovac Attachment Tool demonstrates its full value.

Urban Utility Daylighting

Imagine you are tasked with exposing a bundle of fiber optic cables beneath a busy city sidewalk. You are in a confined space, surrounded by buildings, where a single mistake could cause thousands in damages and disrupt essential services.

In such high-stakes environments, traditional hydrovacing feels risky. Uncontrolled overspray can coat a storefront window in mud, while a slurry-filled hole obscures visibility and elevates the risk of a line strike.

The Hydrovac Attachment Tool transforms this dynamic. Its integrated water jet and focused suction create a clean, controlled excavation. You can remove soil layer by layer while maintaining a clear view of the utilities below. Its agility in tight spaces turns a high-risk job into a professional, straightforward operation.

Residential Trenching and Landscaping

Now, consider a residential project, such as digging a trench for an irrigation system in a meticulously landscaped backyard. The goal is to create a clean, narrow channel without damaging the lawn or splattering mud on the house and patio.

With this attachment, you can achieve precisely that. Because it suctions soil and water simultaneously, the messy slurry is directed into the vac hose instead of across the client's property. The Hydrovac Attachment Tool provides the solution for this clean digging purpose.

This ability to maintain a clean site is a significant selling point for homeowners. It demonstrates respect for their property and minimizes disruption, leaving a lasting positive impression of your work.

This level of surgical digging distinguishes professional hydrovac contractors. To maximize your effectiveness, it is worthwhile to explore various vacuum hose accessories that offer even greater flexibility.

Municipal and Industrial Maintenance

Think of the challenging jobs municipal crews face, like clearing storm drains or culverts clogged with compacted sediment, rocks, and debris. Access is difficult, and removing the blockage is even harder.

With The Hydrovac Attachment Tool, a team can blast and suction in one continuous motion. The high-pressure water breaks up the compacted material, and the powerful vacuum removes it instantly, streamlining a task that once required multiple tools and extensive time.

The same principle applies to industrial cleanup, such as clearing sump pits or removing contaminated soil. The self-contained system ensures hazardous materials are transferred directly from the ground to the tank, protecting the crew and preventing environmental contamination.

Keeping Your Attachment in Fighting Shape

The Hydrovac Attachment is constructed from industrial-grade materials to withstand the harsh realities of a hydrovac site. However, like any essential tool, proper care ensures its longevity and reliability. Consistent maintenance transforms a useful accessory into a core piece of professional equipment that performs dependably, season after season.

The most crucial maintenance step is a quick rinse after each job. Taking a minute to flush out residual soil, mud, and gravel prevents buildup that can degrade suction over time. This simple practice keeps the interior passages clear, ensuring it is ready for the next dig.

Pre-Storage Inspection and Care

Before storing the attachment, perform a quick inspection to identify minor issues before they become major problems in the field.

- Check the Polymer Body: Look for any deep gouges or cracks. Although it is designed for durability, verifying its structural integrity is always wise.

- Inspect the Hose Clamp: Ensure the clamp is clean and the mechanism moves freely. Debris in the threads can prevent a secure seal.

- Confirm Nozzle Cap Integrity: Examine the cap where the wand passes through. A tight, undamaged cap is essential for precise water jet aim.

For storage, a dry location out of direct sunlight is ideal. Placing it in a toolbox or on a shed shelf protects it from the elements and prevents accidental damage. Prolonged UV exposure can degrade even the toughest polymers over time.

Solving Common Problems On-Site

Even the most reliable tools can have occasional issues. Fortunately, most problems with this attachment are easily resolved on-site, minimizing downtime.

The objective is to maximize your time on the job. A field tool requires field-ready solutions—quick fixes that allow the crew to solve a problem in minutes and resume digging.

If you experience a drop in suction or a weak seal, the connection point is the first place to check. Often, a small rock or caked-on mud prevents the hose from seating properly. Simply disconnect it, wipe both ends clean, and reconnect securely.

This practical design reflects broader trends in the vacuum truck industry, a market valued at $2,025.80 million in 2024 and expected to reach $3,597.19 million by 2032. The Hydrovac Attachment, designed for standard 2.5-inch wet vac hoses, exemplifies this evolution—transforming complex systems into nimble, efficient tools. For a deeper industry overview, you can explore these vacuum truck market trends.

Answering Your Questions About the Hydrovac Attachment

When introducing new equipment to experienced hydrovac crews, practical questions are always the first to arise: "Will it work with my setup?" and "Is it tough enough for my jobs?" Let's address the common inquiries from operators about adding The Hydrovac Attachment Tool to their toolkit.

This tool was developed based on real-world industry feedback, so it is designed to integrate seamlessly with the equipment you already use.

What Vacuum Systems Will It Work With?

This attachment was specifically designed to clamp onto the 2.5-inch wet vac hose that is standard across the hydrovac industry. This standardization ensures our tool fits the vast majority of commercial wet/dry vacuums and full-scale hydrovac trucks.

Whether you are connecting to a large truck-mounted system for a major utility locate or a smaller trailer vac for digging post holes, the connection is robust. We use a heavy-duty hose clamp and a durable polymer body to ensure a tight, leak-proof seal, even under maximum suction.

Can It Handle My High-Pressure Washer?

Absolutely. We designed this tool to withstand the high-pressure washers used by hydrovac crews daily. It is made from industrial-grade materials built for the demanding conditions of a typical digging job.

The design is simple and effective: your power washer wand slides through the center, allowing for precise aiming of the water jet while the attachment contains the slurry. It is built to handle the high PSI from commercial-grade washers, so you can operate your equipment at full capacity with confidence.

The purpose of The Hydrovac Attachment Tool is to merge high-pressure water and powerful suction into one streamlined motion. It doesn't just withstand these forces—it channels them to provide superior control and transform a messy, two-person job into an efficient one-tool operation.

How Does This Thing Actually Reduce Cleanup?

The key is containment. In a traditional hydrovac job, water and mud fly everywhere, creating a significant mess that requires extensive cleanup.

This vacuum hose attachment provides the solution by containing the chaos at its source. The shroud around the nozzle captures the slurry of water, mud, and debris as it is created and funnels it directly into the vacuum hose. No more splattering mud across the job site. By preventing the mess from starting, you virtually eliminate post-job cleanup, saving significant time and labor on every dig.

Ready to see how a cleaner, more controlled dig can revolutionize your workday? Discover the solution for effective digging purposes and learn more by visiting Hydrovac Attachment at https://hydrovacattm.com. It’s time to start working smarter, not harder.